Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you looking for a portable laser welder that can weld, cut, and clean seams without needing a bulky water-cooling setup?

Product Overview

You’re looking at the MCWlaser 1500W Laser Welder 2024 Newest Air Cooling 3 in 1 Portable Laser Welding Machine 220V Laser Cleaning & Cutting Welding Seam Cleaner, a compact machine that combines welding, cutting, and cleaning in a single, portable unit. It’s marketed for fast on-site repairs and light-to-medium fabrication work, and it uses a Raycus laser source with the latest 2024 air cooling technology so you don’t need to rely on a water chiller.

What this product promises

The machine promises high-efficiency laser performance, durable construction, ease of operation, and good portability — small enough to fit in a car trunk. You’ll get a handheld gun that’s light and maneuverable, a corrosion-resistant housing to protect internal parts, and safety features such as overheat and dust alarms.

Key Specifications

Below is a quick breakdown of the most important specs so you can get a snapshot of what you’re buying. This helps you decide fast whether its core capabilities match your job needs.

| Attribute | Detail |

|---|---|

| Product name | MCWlaser 1500W Laser Welder 2024 Newest Air Cooling 3 in 1 Portable Laser Welding Machine 220V Laser Cleaning & Cutting Welding Seam Cleaner |

| Laser source | Raycus fiber laser |

| Power | 1500W (laser source capability) |

| Cooling type | 2024 air cooling technology (no external water chiller required) |

| Functions | Welding, cutting, weld cleaning (3-in-1) |

| Input voltage | 220V |

| Size (system) | Compact, ~0.1 m³ |

| Handheld gun weight | 0.69 kg |

| Nozzle | Pure copper, heat-resistant, 360° weld angle |

| Housing | High-temperature corrosion-resistant |

| Continuous operation | Supported (with air cooling limitations considered) |

| Safety features | Overheat/dust alarm; lens protection |

| Warranty | 1 year full machine, 2 years laser source; lifetime online/remote support |

| Typical materials | Stainless steel, carbon steel, aluminum alloys, copper, and similar metals |

Design and Build Quality

You’ll notice the machine has a compact footprint with a high-temperature corrosion-resistant housing that aims to keep the laser and electronics protected from harsh environments. The small size and claimed 0.1 m³ volume make it genuinely portable compared to traditional bench-top laser systems.

Housing, portability, and durability

The housing is built to resist heat and corrosion, which is useful if you plan to use the unit outdoors or in workshop settings where dust and grime are present. The overall design emphasizes portability — you can carry the main unit into a job site and store it in a vehicle trunk without hassle.

Handheld gun ergonomics

The handheld gun is small and light at 0.69 kg, so you can manage longer periods of work with reduced fatigue. The pure copper nozzle is heat-resistant and designed to rotate and allow welding at 360°, which gives you flexibility when you’re working on awkward angles.

Laser Source and Performance

The MCWlaser uses a Raycus fiber laser source, which is a well-known supplier in the fiber laser industry. Raycus modules are generally associated with consistent power delivery, good beam quality, and reliable lifetime performance.

Beam quality and control accuracy

Good beam quality improves focusability and weld penetration, and the Raycus source combined with the machine’s controls promises high control accuracy. For you, that translates into cleaner weld seams, better consistency, and fewer passes for many repair jobs.

Welding speed and continuous operation

The manufacturer highlights fast welding speeds and continuous working capability. With air cooling, continuous operation is supported, though you’ll still need to allow for runtime pauses depending on ambient temperature and the duration of heavy use. In short jobs you’ll see excellent throughput; for very long production cycles, monitor heat build-up.

The 3-in-1 Functions: Welding, Cutting, and Cleaning

You get three distinct capabilities in one package, which can save you money and space versus buying separate machines. Each mode has different setup and parameter needs, but you can switch tasks on-site without changing major hardware.

Welding

Welding is the core function and benefits from the fiber laser’s high energy concentration. You can weld stainless steel, carbon steel, aluminum alloys, and copper with good seam quality when you use the proper settings and technique. It’s well-suited for repair work, seam filling, joining thin plates, and small structure fabrication.

Cutting

Cutting with this unit is oriented toward thin to medium gauge metals. You won’t replace high-power stationary CNC laser cutters, but for quick on-site cuts, trimming, or preparing joint edges, the cutting ability comes in handy. Precision will depend on your fixtures and motion control while cutting.

Cleaning (Weld cleaning / seam cleaner)

Laser cleaning removes oxidation, rust, paint, and burrs from weld seams or substrate surfaces before or after welding. For you, this reduces mechanical prepping time and produces cleaner joints for subsequent welding or finishing.

Materials and Practical Applications

You’ll be able to work on a wide range of metals: stainless steel, carbon steel, aluminum alloys, and copper are all listed as supported. Those cover most repair, fabrication, and maintenance tasks you’ll encounter in workshops or mobile service roles.

Typical application scenarios

This unit is useful for jewelry repair, automotive body and exhaust repairs, HVAC and plumbing on-site fixes, stainless steel kitchen equipment repair, tool maintenance, mold and die touch-ups, agricultural equipment repair, and repair work on marine fittings. If you work on thin- to medium-thickness metallic components and value portability, this could be a fit.

What it’s not ideal for

You shouldn’t expect this machine to replace high-power, water-cooled industrial CNC lasers when cutting thick plates or large series production. Very thick steel plates, precision bevel cutting for fabrication at scale, and high-duty continuous production in hot environments may be better served by larger, dedicated systems.

Recommended Settings by Material (Guideline Table)

These are guideline settings to get you started. Actual results will depend on your joint fit-up, surface prep, laser pulse modes, and travel speed. Use these as a baseline and perform test welds before committing to critical pieces.

| Material | Typical thickness | Suggested power range | Suggested travel speed | Notes |

|---|---|---|---|---|

| Stainless steel | 0.5 – 3 mm | 300–900 W | 200–1200 mm/min | Use short focal distance, clean surface for best finish |

| Carbon steel | 0.5 – 4 mm | 400–1000 W | 250–1000 mm/min | Watch for oxidation; adjust gas shielding if needed |

| Aluminum alloy | 0.5 – 3 mm | 500–1200 W | 150–800 mm/min | Aluminum reflects more; start with preheating and higher power |

| Copper | 0.3 – 2 mm | 600–1500 W | 100–600 mm/min | Copper is highly reflective and conductive—use high power and slower passes |

| Thin cutting | <2 mm< />d> | 300–900 W | 200–1500 mm/min | Use steady motion and a guide for straight cuts |

Note: These ranges are approximate. Always practice on scrap material that matches your workpiece before welding the final part. Adjust parameters to balance penetration and aesthetic finish.

Usability and Controls

If you’re used to traditional welding equipment, you’ll find the MCWlaser 1500W approachable because the company emphasizes simple operation and quick learning. Many users who are new to laser welding can get useful results after brief familiarization.

Control panel and interface

The control interface is designed to be straightforward — you can modify power, pulse parameters, and work mode. Settings differ between welding, cutting, and cleaning functions, so you’ll switch modes based on task. The clarity of controls matters a lot when switching tasks on-site.

Learning curve

Laser welding is different from arc welding, but the learning curve is manageable. With a few hours of practice on scrap you’ll get an intuitive sense for travel speed, focus distance, and pulse settings. If you’re migrating from traditional welders, be prepared to adapt to less filler usage and more emphasis on fit and joint prep.

Operation Workflow: Step-by-Step

Here’s a practical sequence you can follow to perform a typical weld safely and effectively with this machine. Follow manufacturer manuals and local safety rules before operation.

- Prepare the work area: ensure ventilation, clear flammable materials, and set up a stable work surface.

- Inspect the machine: check the housing, cables, and gun. Confirm the nozzle and lens are clean and secure.

- Power on and select mode: turn on the unit at 220V, choose welding/cutting/cleaning mode, and enter baseline parameters.

- Focus and test: set focus distance, perform a test pulse on scrap, and adjust power and speed for the best appearance and penetration.

- Clamp/fixture the workpiece: good fit-up reduces defects and enhances weld quality.

- Perform the weld: maintain consistent travel speed and distance; use the 360° nozzle orientation as needed.

- Post-process: inspect the seam, perform additional cleaning if necessary, and allow cooled parts to be handled safely.

- Turn off and store: power down, clean the nozzle and lens, and store the unit in a dry place.

Quick tips while operating

- Use safety glasses and a welding helmet with appropriate shading for laser work.

- Keep the lens and nozzle free from spatter and dust.

- Allow the unit to rest after long heavy duty cycles to avoid overheating even with air cooling.

- Use clamps and jigs to keep a steady travel speed for the best seam appearance.

Safety Features and Precautions

This machine incorporates alarm functions that warn you about lens overheating, dust accumulation, and other conditions that could reduce performance or increase risk. Safety and proper PPE are non-negotiable when working with lasers.

Built-in alarms and protections

You’ll have alerts for overheating and dust that help protect the optics and internal components. This reduces the failure rate and helps you avoid expensive repairs if you respond to warnings promptly.

Personal protective equipment and environment

Always use laser-rated eye protection and avoid direct eye exposure. Protect skin from high-intensity reflections and use flame-resistant clothing in case of nearby ignition. Operate in well-ventilated spaces or use fume extraction when cleaning or cutting painted or coated metals.

Maintenance, Service, and Support

The MCWlaser package comes with 1 year of maintenance for the whole machine and 2 years maintenance for the laser source, with lifetime online and remote support. That gives you an extended safety net for the most critical component — the laser module.

Routine maintenance tasks

- Clean the nozzle and focusing optics regularly to maintain beam quality.

- Inspect cables and connectors for wear or looseness.

- Ensure air intakes for the air cooling system are free from dust and debris.

- Store the machine in a dry, temperature-stable environment.

Warranty and support expectations

You’ll get one year of general machine maintenance and two years for the laser source. The lifetime online support is useful if you need parameter help, troubleshooting, or remote diagnostics. Make sure you register your unit and document any issues promptly to make warranty claims easier.

Troubleshooting Common Issues

If you encounter problems, many are straightforward to diagnose and fix. Here are typical symptoms and what you can do.

- Weak or inconsistent welds: Check focus distance, nozzle cleanliness, and ensure the beam path is unobstructed. Verify power settings and pulse parameters.

- Overheating alarms: Pause operation and allow the unit to cool. Clear air intake vents and reduce continuous heavy use cycles in hot ambient temperatures.

- Poor cutting performance: Reduce travel speed or increase power; ensure the surface is clean and you’re using appropriate travel guides.

- Lens contamination: Clean the lens gently using approved optical cleaning materials; replace if scratched or damaged.

Pros and Cons

You’ll want a clear, balanced view before you commit. Here’s a concise list of strengths and limitations.

Pros

- True 3-in-1 functionality (welding, cutting, cleaning) in a single portable unit.

- Air cooling eliminates the need for an external water chiller and simplifies on-site use.

- Raycus laser source for reliable beam quality and control precision.

- Compact footprint (~0.1 m³) and light handheld gun (0.69 kg) for portability.

- Durable corrosion-resistant housing and a pure copper nozzle for heat resistance.

- Useful warranty (1 year whole machine, 2 years laser source) plus lifetime online support.

- Alarm functions for overheating/dust protection, increasing safety and reliability.

Cons

- Air-cooling has limits compared to water-cooled high-duty-cycle systems; long production runs may require rest periods.

- Cutting thickness capability is limited compared to industrial stationary lasers.

- For highly reflective materials like copper, you’ll need optimized technique and higher power to get consistent results.

- No integrated CNC motion control — cutting precision depends on manual operation or external fixtures.

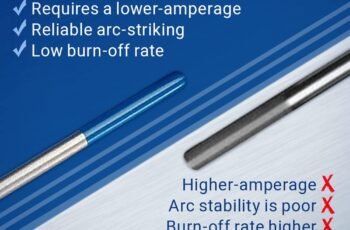

Comparison: Air Cooling vs Water Cooling

If you’re deciding between an air-cooled unit like this and a water-cooled system, think about your workflow and environment. Air cooling gives you portability and simpler setup, which is great for fieldwork and occasional shop use. Water-cooled systems typically provide better temperature stability for long continuous runs and are preferred in production environments where you’ll run high duty cycles day after day.

When to pick air-cooled (this product)

Choose this product if you need mobility, quick setup on job sites, and lower maintenance complexity. It’s ideal for repair technicians who travel and need a single tool for welding, cutting, and cleaning.

When to prefer water-cooled systems

Choose water-cooled machines if you’re running multiple shifts of continuous, heavy-duty welding or if you need to cut thicker plates with absolute repeatability in a production line.

Accessories and Add-Ons to Consider

To get the most from the MCWlaser 1500W, you might add a few accessories that improve workflow and safety.

- Protective laser goggles rated for the specific wavelength.

- Fume extraction or local ventilation for cutting/cleaning painted metals.

- Spare nozzles and protective lenses.

- Portable worktable or fixtures to stabilize parts during cutting/welding.

- Consumable kits and cleaning supplies for optics maintenance.

Who Should Buy This?

You should consider buying this if you fit one or more of the following profiles:

- You’re a mobile repair technician who needs a compact laser for automotive, HVAC, or agricultural repairs.

- You run a small shop doing light fabrication, restoration, or bespoke metalwork.

- You need a multipurpose tool that can weld, cut, and clean without lugging separate machines.

- You prioritize portability and a simple cooling system over high-volume industrial throughput.

Price and Value Considerations

While price will vary by vendor and included accessories, the core value proposition is clear: a single, portable unit that consolidates three functions. If you save on buying separate devices or reduce travel time by fixing things on-site, your return on investment can be rapid. Factor in training time, consumables, and routine maintenance when calculating total cost of ownership.

Frequently Asked Questions

Q: Can you use the MCWlaser for thick plate welding? A: It handles thin to medium thickness more effectively. For very thick plates, multiple passes and fixtures are required, and dedicated high-power stationary systems may be more efficient.

Q: Does the air cooling system limit continuous use? A: It allows continuous operation for many tasks, but prolonged heavy-duty sessions will require intervals to manage heat. Monitor alarms and ambient conditions.

Q: Is filler wire needed for welds? A: Most laser welding on thin materials can be done without filler, but for certain joint designs or thicker sections you might still use filler methods depending on the application.

Q: How important is surface prep? A: Very important. Clean surfaces improve weld quality and reduce defects. Laser cleaning function helps with this by removing oxidation and coatings before welding.

Q: What safety gear is essential? A: Laser-rated goggles, appropriate clothing, and fume extraction for certain materials are essential. Follow local laser and occupational safety guidelines.

Q: How easy is it to learn? A: With some practice on scrap pieces you’ll become competent quickly. The manufacturer emphasizes easy operation to get you started faster.

Final Recommendation

If you want a portable, versatile tool that combines welding, cutting, and cleaning with a reputable Raycus fiber laser source and straightforward air cooling, the MCWlaser 1500W Laser Welder 2024 Newest Air Cooling 3 in 1 Portable Laser Welding Machine 220V Laser Cleaning & Cutting Welding Seam Cleaner is a strong contender. It’s especially compelling for service professionals, small shops, and anyone who needs on-site metalwork without the logistics of large, water-cooled systems. With good maintenance habits and sensible operating limits, you’ll likely find it an efficient and flexible addition to your toolkit.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.