Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

? Are you trying to find a single welding machine that handles MIG, MMA, and Lift TIG without taking up half your garage?

Product overview

You’re looking at the MIG Welder 250A 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine Portable Flux Core Welding Equipment – MIG-130 Welding Machine. This unit promises three distinct welding processes in one compact package, which can simplify your workbench and give you flexibility across different metals and tasks. Below you’ll get a clear, practical review so you can decide whether this welder fits your projects and skill level.

What this machine is designed to do

This model gives you MIG for fast filler transfer, MMA (stick) for outdoor and structural work, and Lift TIG for cleaner, more controlled welds on thin metals. You can switch between gas and gasless MIG, making it useful whether you’re at a shop bench or working outdoors. The manufacturer positions it as suitable for both beginners and professionals, and the controls are intended to be straightforward.

Key specifications

You’ll want the basic numbers in front of you when comparing welders. The table below condenses the main specs so you can quickly see whether the electrical and mechanical capabilities match your needs.

| Feature | Specification |

|---|---|

| Product name | MIG Welder 250A 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine Portable Flux Core Welding Equipment – MIG-130 Welding Machine |

| Welding modes | MIG, MMA (Stick), LIFT TIG |

| Rated current | 250A (max) |

| Power input | Typically 220V single-phase (check your regional version) |

| Wire compatibility | Solid wire and flux-cored wire (dual capability) |

| Gas capability | Gas MIG and gasless flux-cored MIG |

| Portability | Portable, relatively lightweight for a 3-in-1 machine |

| Target metals | Stainless steel, iron (suitable for mild steel) |

| Suitable users | Beginners to professionals |

| Typical accessories | Torch, electrode holder, ground clamp, feed mechanism, regulator (varies by package) |

How these specs matter to you

Those numbers tell you what the machine can handle. A 250A peak output means you can weld fairly thick materials, but actual effective thickness depends on duty cycle and wire/electrode size. Dual wire capability means you aren’t limited to flux-cored fillers—if you prefer MIG with shielding gas for cleaner welds, you can do that too.

What’s included and what to expect in the box

You’ll usually get the core components to begin welding, but package contents vary. Knowing what’s included prevents surprises and ensures you budget for extras like shielding gas, welding helmet, or filler rods.

Typical inclusions

You can expect: the main welding unit, a MIG torch, a ground clamp, an electrode holder for MMA, TIG torch capability (for Lift TIG), an instruction manual, and sometimes a regulator and hose if the seller includes gas accessories. Cables and connectors are usually ready to attach, though minor setup is required.

Extras you may need to buy

You’ll likely need shielding gas (if you want gas MIG or TIG), appropriate filler wire or rods, a welding helmet with an auto-darkening lens, gloves, and possibly spatter anti-stick or anti-spatter spray. If you plan to TIG a lot, consider a quality tungsten and filler rod set and a ceramic cup set for the torch.

Performance by welding mode

You’ll switch among MIG, MMA, and LIFT TIG depending on the joint and metal. Each mode behaves differently, and this machine tries to give you reliable performance across all three.

MIG performance (gas and gasless)

When you use MIG, you can choose gas-shielded solid wire or gasless flux-cored wire. Gas MIG gives cleaner welds with less spatter and better appearance, while flux-cored is forgiving outdoors and faster for thicker work. The MIG feed system in this unit supports both solid and flux-cored wires, which is convenient when you shift between workshop and fieldwork.

You’ll get good deposition rates with MIG at higher currents, making it efficient for fabrication and repair. Expect to adjust wire feed speed and voltage to dial in bead shape, and remember that gas selection (e.g., CO2 or mixed gas) affects penetration and profile.

MMA (Stick) performance

MMA provides robustness outdoors and on rusty or painted surfaces. This machine’s stick mode is handy when you’re working where gas would blow away or when you need to stick weld in awkward positions. The arc characteristics depend on the stick electrode type you choose—7018 for structural, 6013 for general purpose, and so on.

Stick welding is simple to set up: you clamp the work and strike the arc. The machine’s stability at low currents and arc responsiveness will influence how easy you find it to run neat beads.

Lift TIG performance

Lift TIG gives you TIG-style welds without a high-frequency start; you lift the tungsten from the work to initiate the arc. This is gentler on sensitive circuits and reduces HF interference. For thin stainless and mild steel, Lift TIG provides excellent control and cleaner welds than MIG or MMA.

Keep in mind Lift TIG on combo units can be more basic than dedicated TIG machines—if you’re TIG welding exotic alloys or extremely thin gauges regularly, a dedicated TIG with AC balance (for aluminum) might be better. For occasional TIG on steel and stainless, this unit should suffice.

Wire and material compatibility

You’ll want to know what filler consumables to use and which base metals the machine handles well.

Wire types supported

This unit supports both solid MIG wire and flux-cored wire. Solid wire requires shielding gas; flux-cored gives a gasless option. Wire diameters commonly used include 0.6–1.0 mm (approx. 0.023–0.040 in), but check the manual for recommended sizes and drive rolls.

Materials you can weld

You can weld stainless steel and iron (mild steel) easily. With proper setup, you can join thin sheet metal and thicker plate up to the thickness limits dictated by current and duty cycle. For aluminum, MIG is possible only if you equip the machine with a spool gun or proper feed setup—most portable 3-in-1 units struggle with aluminum feed without a spool gun due to softer wire.

Power, duty cycle, and electrode details

You need to match job lengths and thicknesses to your machine’s duty cycle and current output.

Understanding duty cycle and how it affects you

Duty cycle defines how long you can weld at a given current before the unit needs to cool. For a 250A machine, you might expect a rated duty cycle that’s lower at the highest output (for example, 10–30% at 250A) and higher at mid currents. If your job requires sustained high-current work, you’ll need to plan for cooling breaks or use a lower current and multiple passes.

Electrode and wire size impact

Larger electrodes and heavier wire support thicker material and deeper penetration. For MMA, typical electrode sizes are 2.5mm to 4.0mm depending on thickness. For MIG, 0.8–1.0mm flux-cored wire suits thicker joins while 0.6–0.8mm is better for thinner sheet. Match electrode/wire to current and joint thickness for best results.

Setup, controls, and ergonomics

How easy it is to set up the machine and use it daily will drive how much you enjoy and trust it.

Control layout and user interface

This model tends to feature straightforward knobs or digital displays for adjusting current, voltage, and wire feed speed. You’ll appreciate simple labeling for mode selection (MIG/MMA/TIG) and clear feed roll access for wire changes. Good ergonomics mean you can switch modes without fuss and tweak settings on the fly.

Setup steps for common scenarios

- For gas MIG: attach regulator and hose, insert solid wire, set gas flow (around 15–20 CFH as a starting point for CO2 blends), set voltage/wire feed speed.

- For flux-cored MIG (gasless): insert flux-cored wire, switch to gasless MIG setting if available, adjust drive rolls.

- For MMA: attach electrode holder, choose appropriate rod and current.

- For Lift TIG: fit TIG torch and tungsten, set current and polarity (DCEN for steel/stainless), use foot pedal or torch control if supported.

Each setup takes a little time the first few times, but the machine’s intent is to simplify the transitions.

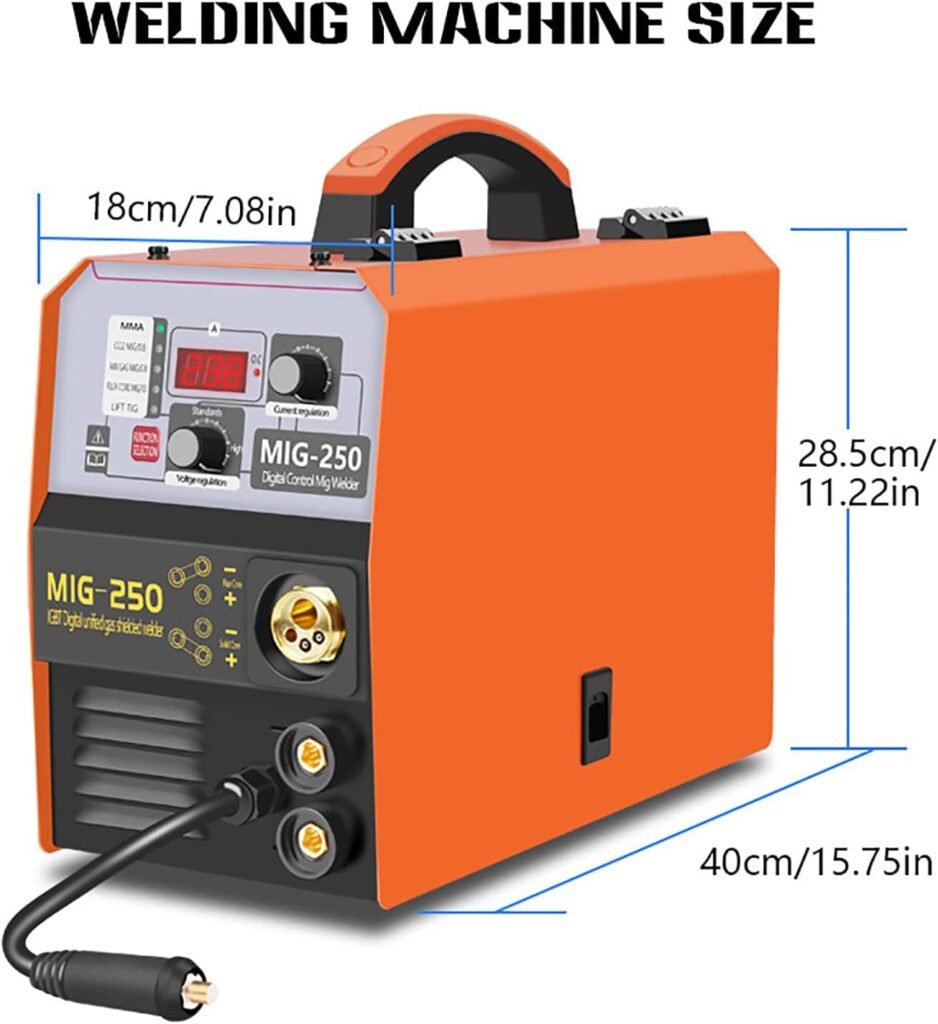

Portability, build quality, and durability

Since the product name includes “Portable,” you’ll likely move it around a job site or garage.

Physical size and weight

This is smaller and lighter than industrial multi-phase welders, but it’s still a metal box with transformer/inverter components. You’ll be able to carry it for mobile projects, but consider a cart or trolley for heavy, prolonged work.

Ruggedness and build expectations

The case and front panel should be robust enough for typical shop use, but you shouldn’t expect industrial IP-rated protection or heavy-duty duty cycles at maximum settings. If you plan on constant outdoor use in harsh conditions, shelter and proper storage will extend the machine’s life.

Welding quality and results

You care about penetration, bead appearance, and fit-up. That’s what really matters on the finished part.

Bead appearance and spatter

Gas MIG will give the cleanest beads with minimal spatter; flux-cored tends to produce more slag and spatter but welds fast and fills well. Stick welding produces slag that you chip away, and Lift TIG yields the cleanest, most controlled beads if you have the skill to run it correctly.

Penetration and strength

Penetration depends on amperage, travel speed, and joint prep. With appropriate settings, the machine can produce structurally sound welds for fabrication and repair on steel and stainless. For critical structural welds, follow relevant code or welding procedure specifications (WPS) and consider preheat/postheat when required.

Safety and accessories

Always protect yourself and your work. This machine is powerful, and proper PPE and setup matter.

Recommended PPE and safety gear

You’ll need a welding helmet (auto-darkening is highly recommended), flame-resistant jacket or apron, welding gloves, safety glasses, hearing protection if grinding, and proper ventilation. For TIG, long sleeves and eye protection for UV exposure are essential too.

Grounding and electrical safety

Make sure you use a properly wired outlet, and check the machine’s grounding. For outdoor use, avoid wet surfaces and use GFCI-protected circuits if possible. Follow local electrical codes and the manual’s guidance.

Who should buy this machine

This 3-in-1 combo unit targets users who value versatility and portability.

Ideal for you if:

- You need multiple welding processes without buying three separate machines.

- You work on steel and stainless with occasional TIG needs.

- You want a portable unit for both shop and light field work.

- You’re a hobbyist or professional who needs a budget-friendly, do-it-all tool.

Not ideal if:

- You need heavy industrial duty cycles for continuous high-amperage welding.

- You weld aluminum frequently and don’t want to add a spool gun or specialized feed.

- You require advanced TIG features (AC welding for aluminum, pulse TIG controls) regularly.

Pros and cons

Summaries help you decide quickly. Below is a concise list of strengths and limitations so you can weigh trade-offs.

Pros

- All-in-one versatility: MIG, MMA, and Lift TIG in a single unit.

- Dual solid wire and flux core capability lets you weld with gas or gasless.

- Portable and relatively compact for a multi-process machine.

- Suitable for both beginners and experienced welders with simple controls.

- Affordable compared to buying separate machines for each process.

Cons

- Duty cycle limitations at maximum amperage; may need cooling breaks.

- Lift TIG lacks some advanced features of dedicated TIG machines (no AC for aluminum).

- Aluminum MIG feed may require additional accessories (spool gun) for reliable feeding.

- Build quality can vary by batch/vendor—inspect the unit and seller reputation.

Comparison with similar options

When you compare multi-process welders, you weigh price, duty cycle, and real-world usability.

How it stacks up

Compared to entry-level single-process welders, this unit gives far more flexibility. Compared to more expensive multi-process inverter welders, it may lack advanced digital controls or the highest duty cycles but often costs less. If you prioritize budget and the combination of MIG/MMA/TIG, this model is a compelling middle-ground.

Quick comparison table

| Aspect | MIG-130 (3-in-1) | Cheap single-process MIG | Dedicated TIG/Industrial Multi-process |

|---|---|---|---|

| Modes | MIG, MMA, Lift TIG | MIG only | TIG + MIG + MMA (higher specs) |

| Portability | High | High | Lower (heavier) |

| Price | Mid-range | Low | High |

| TIG capability | Lift TIG (DC only) | None | Full TIG (AC/DC, pulse) |

| Duty cycle | Moderate | Varies | High |

| Ease of use | Good | Easy | Moderate to advanced |

Common real-world applications

You’ll find multiple uses across fabrication, repair, maintenance, and hobbyist projects.

Typical jobs this handles well

- Automotive body and frame repairs (MIG for fillers, TIG for precise work).

- Metal furniture, gates, and railings fabrication.

- Farm and agricultural repairs where flux-cored MIG and stick welding are common.

- Small stainless fabrication and repair where TIG finish is useful.

Jobs to be cautious about

- Aluminum-intensive shops without a spool gun or dedicated aluminum feed system.

- Heavy industrial production requiring long, continuous weld cycles at high amperage.

Tips to get the best results

Small habits and setup choices change your welding quality dramatically.

Setup and tuning tips

- Start with manufacturer-recommended settings for wire size and thickness, then tweak voltage and wire feed speed in small increments.

- Use a test coupon to tune settings before welding your actual workpiece.

- For flux-cored welding outdoors, increase voltage slightly and slow down travel speed for deeper penetration.

- Keep drive rolls clean and match the groove type to the wire (U-groove for flux-cored, V-groove for solid wire).

Maintenance tips

- Regularly clean the MIG torch contact tips and replace worn liners for consistent feeding.

- Check and tighten electrical connections periodically to avoid overheating.

- Keep the unit in a dry, ventilated area and clear dust from vents.

- Inspect cables and insulation for wear; replace damaged leads immediately.

Accessories and consumables to consider

To make this machine more versatile and comfortable to use, pick up a few extras.

Highly recommended

- Auto-darkening welding helmet (for eye comfort and productivity).

- Quality MIG and TIG torch consumables (tips, nozzles, cups).

- Spool gun or push-pull feeder if you plan to weld aluminum.

- Regulator and appropriate shielding gases (Argon for TIG/stainless MIG mix for carbon steel).

- Extra contact tips, drive rolls, and a selection of electrodes/wires.

Troubleshooting common issues

You’ll run into a few predictable challenges. Here’s how to fix them quickly.

Wire feeding problems

If the wire jams or birdnests, check the drive rolls, liner, and spool tension. Replace worn liner and use the correct drive roll groove. Keep the feeder path straight and reduce spool backlash.

Porosity in MIG welds

Porosity usually indicates contamination or insufficient shielding gas. Check gas flow, hose connections, and that the nozzle is free of spatter. Clean the base metal from rust, oil, or paint before welding.

Unstable arc in TIG mode

If Lift TIG arc initiation is inconsistent, ensure proper tungsten preparation, correct electrode tip shape, and a clean torch setup. Confirm correct polarity and that the torch is properly grounded.

Final recommendation

You’ll get a lot of capability for the money with the MIG Welder 250A 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine Portable Flux Core Welding Equipment – MIG-130 Welding Machine. If you need versatile functionality—MIG (gas and gasless), MMA, and Lift TIG—in a portable package at a mid-range price point, this is a very pragmatic choice.

If your work demands continuous heavy-duty production or advanced TIG features for aluminum, consider stepping up to a dedicated, higher-specification machine. But for mixed shop and field work, hobbyists, and professionals who need flexibility without owning three separate welders, this unit is well-suited.

Quick buying checklist

Before you purchase, make sure you tick off these points so the unit meets your needs.

- Confirm the machine’s input voltage matches your power supply.

- Verify the duty cycle at the currents you expect to use.

- Check whether the package includes the accessories you need (regulator, torch consumables).

- Plan for additional PPE and consumables (gas, wire, electrodes).

- Read reviews from other users about long-term reliability and seller support.

If you follow this guidance, you’ll be able to set up the MIG Welder 250A 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine Portable Flux Core Welding Equipment – MIG-130 Welding Machine to achieve clean, strong welds across a wide range of projects.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.