Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable MIG welder that can handle both gas and gasless welding for workshop and light industrial jobs?

Overview of the Mig Gas Gasless Welder Euro Torch MB25 4 Metre 230A Welding 6003

You’ll find that the Mig Gas Gasless Welder Euro Torch MB25 4 Metre 230A Welding 6003 is designed to be versatile for both hobbyists and small professional shops. The name alone suggests a unit that supports gas-shielded and gasless welding, offers a robust MB25 torch, and gives you 230 amps of output with a 4-metre torch lead.

What this product aims to do

This machine aims to let you switch between gas and gasless MIG welding to match job needs and material availability. You can expect reasonable duty cycles and capability to weld a variety of metals, although exact performance depends on the internal components and build quality.

Key Features

You should look for features that matter to your workflows like switching between gas and gasless, a quality torch, adjustable current, and a long cable. The Euro Torch MB25 designation suggests compatibility with common MB-style torches which are popular for comfort and reliability.

Torch: Euro Torch MB25

The MB25 torch is a widely used style that gives you comfortable handling and good trigger responsiveness. Since your torch lead is 4 metres long, you’ll get greater reach around your workspace without constantly moving the machine.

Output: 230A

A 230A maximum output typically means you can weld thicker materials and work for longer periods on moderate thicknesses. For you, this usually translates to welding mild steel sheets up to a decent thickness and handling thicker welds with multiple passes.

Specifications

Below is a breakdown of the main specifications you should consider. These are drawn from the model name and common features of similar machines, so you can compare and set expectations before buying.

| Specification | Typical Value / Notes |

|---|---|

| Model Name | Mig Gas Gasless Welder Euro Torch MB25 4 Metre 230A Welding 6003 |

| Welding Type | MIG (Gas & Gasless / Flux-Cored) |

| Torch Type | Euro Torch MB25 |

| Torch Lead Length | 4 metres |

| Max Output Current | 230 A |

| Duty Cycle | Varies by manufacturer (commonly 60% @ 150-200A) |

| Input Voltage | Usually 220-240V single phase (confirm before purchase) |

| Wire Size | Typically 0.6 mm – 1.2 mm depending on feed unit and rollers |

| Wire Types Supported | Solid MIG wire (with gas) & Flux-cored wire (gasless) |

| Gas Compatibility | Argon mixes/CO2 blends for solid wire |

| Typical Applications | Auto body repair, fabrication, general maintenance |

| Cooling | Fan-cooled (common) |

| Weight | Varies, usually medium-weight bench/portable unit |

How you should use the table

Use this table as a quick reference to match your project needs like power, portability, and wire compatibility. If any specific spec is critical to you (like duty cycle or input voltage), confirm with the seller or manual before purchase.

Design and Build Quality

You’ll notice whether a welder is well-built in the way the case, controls, and torch feel in your hands. Solid build quality typically means longer service life and fewer issues with electrical connections or feed mechanisms.

Case and chassis

A sturdy metal case with decent ventilation will help the internal components stay cool and protected in a shop environment. Lightweight consumer models can skimp on protection, so make sure weld spatter, moisture, and knocks won’t damage the unit.

Controls and front panel

Look for clear controls and readable markings so you can set voltage and wire feed speed accurately. If the machine provides a few presets or a straightforward voltage/wire-speed chart, you’ll spend less time dialing in welds.

Performance and Welding Results

Your real measure of performance is the weld bead quality, penetration, spatter level, and ease of arc control. This machine’s 230A rating gives you headroom for heavier welds, but you’ll need to match wire, gas, and settings properly to get optimal results.

Arc stability

A well-designed MIG unit will give you a stable arc across a range of wire speeds and voltages. For gasless welding, arc stability depends heavily on flux-cored wire quality and proper wire feed setup.

Spatter and finish

Using gas-shielded solid wire usually gives you cleaner welds with less spatter, while gasless flux-cored wire tends to produce more spatter but allows better outdoor use without wind-sensitive shielding gas. You should expect to spend a bit more time grinding with gasless welds unless wire and settings are tuned.

Usability and Controls

You want a machine that’s easy to operate with minimal fuss when switching modes and setting parameters. Intuitive controls reduce setup time and mistakes, and a clean torch trigger feel makes long jobs less fatiguing.

Switching between gas and gasless

Check how the unit switches between gas and gasless modes — ideally, it’s a simple matter of selecting wire and gas or running flux-cored wire without gas. Your spool hub and drive rollers should accommodate flux-cored wire easily.

Wire feed and tensioning

A reliable wire feed system with adjustable tension, correct rollers for wire diameter, and a responsive drive motor will save you headaches from bird-nesting and inconsistent welds. You should always check and set the tension for the wire type you’re using.

Torch and Cable

The Euro Torch MB25 design is comfortable and popular because it is relatively lightweight and easy to manoeuvre for extended periods. A 4-metre cable gives you mobility and reduces the need to move the power unit constantly.

Ergonomics and trigger

You’ll appreciate a torch that sits comfortably in your hand and has a tactile, trouble-free trigger. A poor trigger design will wear you down on longer welds and may be prone to sticking or intermittent contact.

Cable management and strain relief

Good strain relief at the torch head and machine end will prevent premature cable wear. Ideally, the 4-metre lead should be flexible but robust so you can route it through tight spaces without damaging the internal conductors.

Setup and Installation

You want a straightforward installation process with minimal tools and clear instructions. Proper setup includes wire loading, roller selection, contact tip selection, grounding, and gas connection if you use gas.

Loading wire and adjusting rollers

When you first set up your machine, feed the wire carefully and set the rollers to match the wire diameter. Too loose and the wire will slip; too tight and the wire will deform or grind into the roller.

Gas hookups and regulator setup

If you plan to use gas shielding, ensure you have a compatible regulator and that the gas flow rate is correct for your wire and welding position. For CO2 or mixed gases, flow rates typically range from 10–20 liters per minute, but check manufacturer recommendations.

Materials and Thickness Capability

You’ll want to know what thicknesses and material types you can tackle with this welder. The 230A rating indicates capability to handle mild steel, stainless, and with appropriate wire and shielding, some thin aluminum tasks (with additional equipment).

Mild steel performance

For mild steel, your machine should weld sheet metal around automotive body thickness up to plate material in multiple passes. With correct settings, you can expect good penetration and bead appearance on material up to typical thicknesses that match the amp range.

Other metals like stainless and thin aluminium

Stainless welding uses similar settings to mild steel but may require a different wire and gas mix for optimal results. Welding thin aluminum typically requires spool gun or special wire feed adjustments — the standard torch feed may struggle with soft aluminum wire unless the feed system is optimised.

Duty Cycle and Cooling

Duty cycle determines how long you can weld at a given amperage before the machine needs to cool down. You should consider whether the duty cycle matches the rhythm of your work or whether you’ll need breaks or multiple machines for continuous production.

Typical duty cycle expectations

Units in this power range commonly have duty cycles like 60% at lower amps and a reduced duty cycle at maximum output. If you frequently weld at or near the maximum current for long intervals, you’ll need a machine with a higher duty cycle or plan for rest periods.

Cooling system and fan noise

A cooling fan is standard and keeps electronics within a safe temperature band, but it can add noise to your workspace. Adequate ventilation slots and a clean fan help prevent overheating and extend the life of your machine.

Safety Features

Your safety depends on both standard welding practices and built-in machine protections. Look for features like thermal overload protection and robust earth clamp connections to protect both you and the machine.

Thermal protection and fusing

Thermal cutouts and proper internal fusing protect the machine from overcurrent situations. You should still evaluate your workshop’s power supply and ensure proper breakers and grounding are in place.

Handling fumes and ventilation

Welding produces fumes and gases that you must handle with local exhaust or proper ventilation. For gasless flux-cored welding, fume levels can be higher, so you should plan for appropriate PPE and extraction.

Maintenance and Care

Maintaining your welder keeps it reliable and reduces downtime. Regular checks, cleaning, and correct replacement parts will make the machine last longer and perform more consistently.

Routine cleaning and inspection

You should regularly check the wire feed components, gas lines, and contact tips for wear and contamination. Clean the wire feed path, replace worn tips, and keep cooling vents clear of dust and spatter.

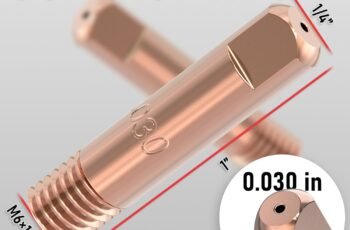

Consumables and replacement parts

Keep spare contact tips, nozzles, and drive rollers on hand for the wire sizes you use most. Buying OEM or high-quality consumables will reduce feeding issues and maintain arc quality.

Troubleshooting Common Issues

You’ll inevitably encounter problems like poor feed, inconsistent arc, or spatter. Most issues are solvable with a few checks and basic adjustments.

Wire bird-nesting and feed problems

If the wire nests on the spool, make sure the spool is seated properly and the tension is correct. Also check that the liner and drive rollers match the wire type — steel vs. flux-cored wires may require different rollers.

Inconsistent arc or intermittent welding

An inconsistent arc can come from worn contact tips, poor earth connection, or contaminated wire. Inspect the contact tip for wear, tighten cable connections, and ensure the ground clamp is secure and clean.

Pros and Cons

You should weigh benefits and drawbacks based on how you work and what you weld most often. Here’s a general rundown based on the model’s typical capabilities.

Pros

- You get dual-mode capability (gas and gasless) for flexible application choices.

- The MB25 torch and 4-metre lead give you comfortable reach and handling for many tasks.

- 230A max current provides headroom for thicker material and more demanding work.

- Euro torch style makes replacement parts widely available and familiar to many users.

Cons

- Exact duty cycle and real-world output can vary, so you may find limitations for continuous heavy production.

- If aluminium welding is a key requirement, the standard setup may need a spool gun or additional accessories.

- Noise from cooling fans and spatter in gasless mode can require additional cleanup and fume extraction.

Comparison with Similar Models

You’ll want to compare this unit to other mid-range MIG machines on portability, duty cycle, and feature set. Compare build quality, warranty, accessories, and consumable support when deciding.

Versus entry-level consumer MIGs

Compared to basic hobby units, you’ll likely get better features, more current, and a sturdier torch with the Euro Torch MB25. If you need more than occasional repairs, the extra capacity is worth it.

Versus higher-end professional units

Higher-end professional units may offer digital controls, higher duty cycles, better wire feeding systems, and integrated spool guns for aluminium. If you plan full-time production, weigh the extra cost against long-term productivity and reliability.

Accessories and Upgrades You Should Consider

Your welding setup is more than the power unit; the right accessories make a huge difference in performance and comfort. Think about what will make your work easier and safer.

Recommended consumables and spares

Keep extra contact tips, nozzles, drive rollers, and a few different wire diameters. Carry a few spare liners and a replacement MB25 torch handle or head if you weld heavily.

Optional accessories

Consider a spool gun for aluminum, a dedicated welding cart, external gas regulator, or fume extraction arm. A quality welding helmet with auto-darkening and a good ground clamp are also must-haves.

Who Should Buy the Mig Gas Gasless Welder Euro Torch MB25 4 Metre 230A Welding 6003

This machine is a good match for you if you work on automotive repairs, general fabrication, or maintenance where flexibility between gas and gasless is valuable. It’s also helpful for hobbyists upgrading beyond basic tack welders who want more versatility and reach.

Ideal use cases

You’ll benefit from this welder in bodywork, farm equipment repair, DIY projects, and small fabrication shops. If you need portability with a serious amp range and a widely supported torch interface, this model fits well.

Less suitable users

If you’re welding aluminium regularly without a spool gun or you need continuous heavy production at maximum current, you might need to consider higher-end alternatives. Similarly, if you require the quietest possible environment, the typical fan-cooled design will be noticeable.

Buying Tips and Checklist

Before you buy, verify the real specifications and included accessories with the seller. Use this checklist to make sure the machine matches your expectations.

Pre-purchase checklist

- Confirm input voltage and plug type for your workshop.

- Verify duty cycle at useful amperages for your intended projects.

- Check whether gas regulator and hose are included if you plan to use solid wire.

- Ensure the MB25 torch and cable length are as advertised and that spare consumables are available.

- Read customer reviews for real-world reliability and support experiences.

Warranty and support

Look for a reasonable warranty period and accessible technical support. You’ll appreciate a supplier with replacement parts and clear documentation when you need consumables or repairs.

Final Verdict

If you want a flexible mid-range MIG welder that can handle gas and gasless welding with a familiar MB25 torch interface and a long 4-metre lead, this unit could serve you well. It’s a practical choice for many hobbyists and small shops, provided you verify duty cycle, input requirements, and accessory availability before purchasing.

Practical next steps

Test or inspect the machine in person if possible, or confirm returns and warranty terms when ordering online. Make sure you have the right safety gear, shielding gas (if needed), and consumables to get started right away.

Quick Reference Summary Table

Here’s a compact comparison to help you decide at a glance.

| Category | Short Takeaway |

|---|---|

| Best for | Hobbyists, small shops, auto body, maintenance |

| Strengths | Gas/gasless flexibility, MB25 torch, 4m lead, 230A capability |

| Limitations | Duty cycle and continuous heavy use, aluminum requires accessories |

| Must-check | Input voltage, included accessories, duty cycle specs |

| Accessories to buy | Contact tips, nozzle spares, spool gun for aluminum, regulator |

If you want, I can help you draft a quick email to a seller to confirm specs, or create a list of must-have consumables and safety gear tailored to the welding work you plan to do.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.