Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you trying to decide if the MIG MMA TIG 3 in 1 Combo Inverter Welder 270A/250A/200A/160A Welding Machine is the right multi-process welder for your projects?

Product Overview

You’re looking at a multi-process inverter welder that promises versatility by combining MIG, MMA (stick), and TIG processes in a single unit. The product name — MIG MMA TIG 3 in 1 Combo Inverter Welder 270A/250A/200A/160A Welding Machine for Steel and Iron Aluminum Repairing for Comfort Work (Color : MIG 200A, Size : Type) — indicates several output options and focuses on comfort and repair work for steel, iron, and aluminum. The manufacturer highlights an integrated wire feeder, adjustable voltage/current, and accessories geared toward home repairs and hobby welding.

Key Features

Under this heading you’ll find the most important selling points that affect everyday use and results. These features are oriented toward giving you a flexible machine for a range of light-to-medium welding tasks.

- 3-in-1 functionality: MIG, MMA, and TIG modes allow you to switch processes based on the job.

- Integrated wire feeder: Meant to provide a smooth, steady wire feed for MIG work.

- Adjustable welding voltage and current: Lets you tailor heat and penetration to material thickness and joint type.

- Full-size MIG platform and powerful motor: Designed for longer runs and consistent wire feed speeds.

- Portable design with comfortable handgrip: Easier to carry to jobsites and around the workshop.

- Included accessories: Folding mask, brush, slag hammer, and 1 kg of 1.0 mm carbon steel gas-shielded wire.

- Targeted for thin steel and iron, and repair work on aluminum (note: aluminum TIG/MIG often needs special setup).

What the 3-in-1 Design Means for You

Combining three welding processes in one inverter gives you flexibility without buying three separate machines. You can handle light fabrication, repairs, and hobby projects with fewer gear swaps. Keep in mind that true professional-grade performance across all three processes often requires additional accessories or setup (for example, quality TIG torches or spool guns for aluminum MIG).

What’s Included in the Box

You should know exactly what arrives so you can plan the first setup and identify any additional purchases.

- The welder unit (configured according to the chosen amperage option)

- Integrated wire feeder installed on the unit

- Folding welding mask

- Wire brush

- Welding slag hammer

- 1 kg spool of 1.0 mm carbon steel gas-shielded welding wire

- Basic cables and connectors (ground clamp and electrode holder typically included — check your specific listing)

- User manual and basic consumables (if noted by seller)

| Item Included | Purpose & Notes |

|---|---|

| Integrated wire feeder | For MIG wire feed; ensures consistent wire delivery during MIG welding |

| Folding mask | Basic eye and face protection for welding; consider upgrading to an auto-darkening helmet for convenience |

| Wire brush & slag hammer | Cleaning and slag removal after welding, especially for MMA/stick work |

| 1 kg carbon steel 1.0 mm wire | Ready-to-use for gas-shielded MIG on steel; you’ll still need shielding gas unless this is flux-cored wire (confirm with seller) |

| Ground clamp & electrode holder | Essentials for electrical connection and stick welding |

| User manual | Contains setup, wiring, and safety guidelines — read before use |

Technical Specifications (At-a-Glance)

Below is a summarized table of the main technical points you can derive from the product name and description. Because the listing indicates multiple models and options (270A/250A/200A/160A), make sure you confirm the exact model you purchase.

| Specification | Details (as listed / typical) |

|---|---|

| Machine type | 3-in-1 Inverter Welder (MIG, MMA, TIG) |

| Amperage options | 270A / 250A / 200A / 160A (select model) |

| Included wire | 1 kg, 1.0 mm carbon steel gas-shielded wire |

| Wire feeder | Integrated, full-size platform |

| Adjustable controls | Voltage and welding current adjustable |

| Target materials | Steel, iron, aluminum (repair work) |

| Portability | Lightweight, compact, with handgrip |

| Accessories | Folding mask, brush, slag hammer, wire spool |

| Typical use | Home DIY, general repairs, hobbyist, small professional jobs |

| Cooling | Likely fan-cooled (confirm on manual) |

| Power input | Confirm from product listing/manual (often 220–240V for models like these) |

| Duty cycle | Not specified — check manufacturer specs for your chosen amperage |

Notes About the Specs

Because multiple amperage and model variations are listed in the name, you need to verify the exact specs before buying. Output amperage directly impacts the thickness of material you can weld effectively and the duty cycle (how long you can weld before the machine needs to cool). If duty cycle and input voltage aren’t explicitly listed in the description you see, ask the seller or consult the manual.

Setup and First Use

Getting the machine set up correctly will save you frustration and help you produce stronger welds faster. You’ll want to follow the manual closely, but here are practical steps you’ll likely follow.

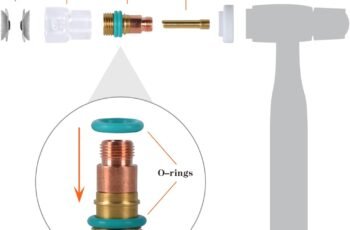

First, unpack the unit and check for damage or missing items. Make sure the wire feeder has the spool installed correctly and the wire is threaded through the drive rolls and liner. Inspect the included consumables — contact tip, nozzle, and drive roll — and confirm they match the wire diameter (1.0 mm in the included spool).

Connect the welding cables: ground clamp to the workpiece and MIG gun or electrode holder to the machine. If you plan to MIG weld with gas, ensure you have the proper shielding gas and regulator (the listing includes gas-shielded wire but not a gas cylinder or regulator). For TIG work, you’ll typically need a TIG torch, shielding gas, and a gas valve/controller — confirm what is included and what must be purchased separately.

Before your first weld, set an initial voltage and wire feed/current based on the wire size and material thickness, then test on scrap metal. Make incremental adjustments while observing bead shape and penetration.

Quick First-Use Checklist

- Inspect machine and accessories.

- Confirm model and input voltage compatibility with your electrical supply.

- Install and thread MIG wire correctly.

- Attach ground clamp to clean, bare metal.

- Confirm shielding gas and regulator if MIG/TIG require it.

- Set conservative starting parameters and test on scrap.

- Wear appropriate PPE: helmet, gloves, jacket, and ventilation.

Performance and Welding Quality

You’ll find that adjustable voltage and current, combined with a robust wire feeder, are the central contributors to weld quality. The integrated wire feeder claims to provide steady wire speed, which is crucial for smooth MIG beads and fewer burn-throughs on thin metal.

For thin steel and iron repairs, the machine’s ability to fine-tune output helps minimize warping and burn-through. Stick welding (MMA) is useful outdoors and on dirty or rusty surfaces. TIG mode gives you finer control for thin materials and cleaner welds, though achieving consistent TIG results often depends on torch quality and gas purity.

Real-World Expectations

If you’re using a basic included mask and the machine’s stock MIG gun, expect competent results suitable for DIY, bodywork, small structural repairs, and hobby projects. For heavy or precision TIG welding on aluminum, you might need a separate spool gun or better TIG torch and pulsed TIG features, which may not be available on this basic combo unit.

Portability and Design

You’ll appreciate the compact form factor and comfortable handgrip when you need to move the machine around a garage or carry it to a jobsite. The lightweight design helps if you’re often working alone or in tight spaces.

That said, portability sometimes means trade-offs in cooling capacity and duty cycle compared to larger shop machines. If your projects require long, continuous welds at high amperage, be mindful of rest cycles and machine heating.

Accessories and Extras

The included extras are practical for starting out on small jobs. A folding mask, wire brush, and slag hammer allow you to handle basic prep, welding, and cleanup without buying immediate extras. The 1 kg spool of 1.0 mm wire gets you started on MIG welding, but check whether the wire is gas-shielded or flux-cored; gas-shielded wire requires a gas cylinder for proper MIG welds.

| Accessory | Benefit |

|---|---|

| Folding mask | Basic protection; good for occasional use but less convenient than auto-darkening helmets |

| Wire brush | Cleans slag and prepares surfaces for welding |

| Slag hammer | Breaks off slag after MMA welding |

| 1 kg 1.0 mm wire | Allows immediate MIG practice on thin steel; confirm gas requirements |

| Ground clamp & electrode holder | Essentials to get started with MMA and grounding |

Should You Upgrade Accessories?

If you plan to weld frequently, consider upgrading to an auto-darkening helmet, better MIG/TIG torches, a proper gas cylinder and regulator, spare contact tips and nozzles, and a higher-quality ground clamp. These upgrades improve convenience, safety, and weld quality.

Safety Features and Precautions

Safety should be non-negotiable. The machine itself may include standard protections like thermal overload and fans, but you must follow safe practices every time you weld.

- Always wear appropriate PPE: helmet with correct shade, welding jacket, gloves, and ear protection.

- Ensure proper ventilation; welding produces fumes and gases that are hazardous in confined spaces.

- Use the correct shielding gas and consumables for MIG/TIG to minimize fumes and spatter.

- Inspect cables, connectors, and ground clamps before use for damage.

- Keep flammable materials away from the work area.

- Follow lockout/tagout and electrical safety practices if you’re connecting or servicing internal components.

Maintenance and Care

Routine maintenance will keep the unit reliable and extend its life. Basic maintenance you can perform includes:

- Cleaning dust and spatter from the wire feeder, drive rolls, and cooling vents.

- Replacing worn contact tips, nozzles, and liners as needed.

- Checking wire spool tension and drive roll condition.

- Ensuring tight electrical connections and corrosion-free terminals.

- Storing in a dry, temperature-stable place to avoid moisture damage to electronics and spools.

Preventive Tips

- Blow out the machine with compressed air (power off) periodically to remove fine metal dust.

- Keep a small kit of spare consumables and fuses handy.

- Calibrate wire feed and ensure the correct drive roll for the wire diameter to reduce bird-nesting and feed issues.

Practical Welding Tips for Best Results

You’ll get better welds faster if you adopt a few practical habits.

- Clean the base metal: Remove paint, oil, and heavy rust from joint areas for MIG and TIG.

- Use the right wire and electrodes: Match diameter and type to material and thickness.

- Set conservative settings first: Start low on heat to avoid burn-through on thin metal and increase gradually.

- Practice bead technique: Consistent travel speed and angle produce stable penetration and bead shape.

- For aluminum MIG, consider a spool gun: The standard MIG gun’s long liner can cause feeding problems with soft aluminum wire.

- For MMA, choose the right electrode coating and polarity for the job.

Pros and Cons

You deserve a clear breakdown of likely benefits and limitations so you can make an informed decision.

Pros:

- Versatile 3-in-1 functionality saves space and money compared to buying three separate machines.

- Integrated wire feeder and adjustable voltage/current simplify MIG setup and tuning.

- Portable and lightweight for on-site repairs and hobbyist use.

- Useful accessory kit included for basic welding and cleanup.

- Suitable for thin steel and iron repairs and general DIY applications.

Cons:

- Full professional performance for TIG or aluminum MIG may require additional torches or accessories.

- Duty cycle and detailed specs aren’t clearly listed in the provided description — verify before heavy usage.

- Included folding mask is basic; auto-darkening helmets are better for frequent welding.

- Cooling/thermal management of portable inverters may limit continuous high-amperage use.

- You may need to buy gas, regulator, and additional consumables depending on welding choices.

Who Should Buy This

This combo welder suits a range of users depending on priorities:

- You as a DIYer or hobbyist: If you want a single machine to handle car repairs, furniture repair, metal art, or home maintenance, this unit is a practical starting point.

- You as a mobile repair technician: The portable design makes it convenient to take to small jobs, farm repairs, or roadside fixes.

- You as a beginner: The included accessories let you start practicing quickly; just ensure you get proper protective gear.

- You as a small workshop owner: This machine can handle light fabrication and repair work, but for heavy industrial tasks or long continuous welds, invest in a higher-duty-cycle machine.

If you need high-end TIG for aluminum aero or precise stainless work, or long production runs at high amperage, consider a dedicated machine or higher-tier combo with better duty cycle and accessory support.

Comparison With Single-Process Machines

A single-process MIG, TIG, or MMA machine typically offers optimized features for that process — better wire feeders, more refined amperage control, higher duty cycles, or advanced TIG controls. The trade-off with a 3-in-1 unit is convenience versus specialization.

- Convenience: Buy once, switch processes for multiple job types.

- Specialization: Dedicated machines generally deliver better process-specific performance and may include advanced features like pulse TIG, high-frequency starts, or spool-gun compatibility for MIG aluminum.

If your workload is varied and you value flexibility, a 3-in-1 inverter makes sense. If you mostly do TIG stainless and aluminum, or high-volume MIG production, a dedicated machine will perform better.

Frequently Asked Questions (FAQs)

You’ll likely have practical questions; here are simple answers to common concerns.

Q: Does the welder include shielding gas for MIG/TIG? A: The package includes 1 kg of 1.0 mm carbon steel gas-shielded wire, but typically does not include a gas cylinder or regulator. Confirm with the seller whether the wire is gas-shielded or flux-cored, and purchase the appropriate gas/regulator if required.

Q: Can it weld aluminum effectively? A: The machine supports aluminum repairing in name, but MIG welding aluminum usually requires a spool gun or a short, smooth liner to avoid feeding problems. For TIG aluminum, you’ll need a TIG torch and high-purity argon gas, plus practice for good results.

Q: What amperage should I choose? A: Choose the model based on the maximum thickness you expect to weld. Higher amperage capability lets you weld thicker sections, but also brings higher power requirements and potentially larger duty cycle heat. For most home projects, 160A–200A options are common; heavier repair work might benefit from 250A–270A options.

Q: What’s the duty cycle? A: Duty cycle isn’t specified in the provided details. Contact the seller or check the manual for the exact model to determine how long you can weld at a given amperage before cooling is required.

Q: Is it good for automotive bodywork? A: Yes, for thin steel MIG and MMA repairs, this kind of unit is useful. Use lower heat settings to avoid warping and practice on scraps to dial in your settings.

Troubleshooting Common Issues

You’ll encounter issues occasionally; here are straightforward fixes.

- Wire feeding poorly or bird-nesting: Check drive roll pressure, spool tension, liner condition, and correct drive roll for wire diameter.

- Spatter or inconsistent bead: Adjust voltage and wire feed speed; check shielding gas flow and nozzle cleanliness.

- Machine overheats: Allow cooling rests between welds and verify duty cycle limits. Ensure vents aren’t clogged with dust.

- Poor TIG arc: Confirm gas flow, clean tungsten, and check torch grounding and connections.

Final Recommendation

If you need a flexible, portable machine for general repairs, DIY projects, and hobby welding, the MIG MMA TIG 3 in 1 Combo Inverter Welder 270A/250A/200A/160A is a practical value proposition. It offers the convenience of three processes in one package, an integrated wire feeder for stable MIG welding, and handy starter accessories. Before you buy, confirm the exact model specs (amperage, input voltage, duty cycle), verify whether shielding gas is required or included, and plan to upgrade PPE and perhaps torches if you’ll be doing frequent TIG or aluminum work. With proper setup and practice, this unit should serve you well for general repair and light to medium welding tasks.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.