Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a compact, multiprocess welding machine that can handle MIG, MMA (stick), and TIG tasks whether you’re working in your garage or out on a job site?

Quick verdict

You get a versatile 3-in-1 welder that’s designed to be beginner-friendly and portable while still offering useful features for hobbyists and light professionals. The One-Knob intelligent control and gasless flux-core capability make setup faster and reduce the learning curve, but expect limitations for heavy industrial work.

Product overview: MIG Welder, 3 in 1 Combo MMA/MIG/TIG Welding Machine, Supports Gasless Welding (Requires Argon Gas), Portable Welding Machine for Outdoor Welding, Steel, Iron Frame

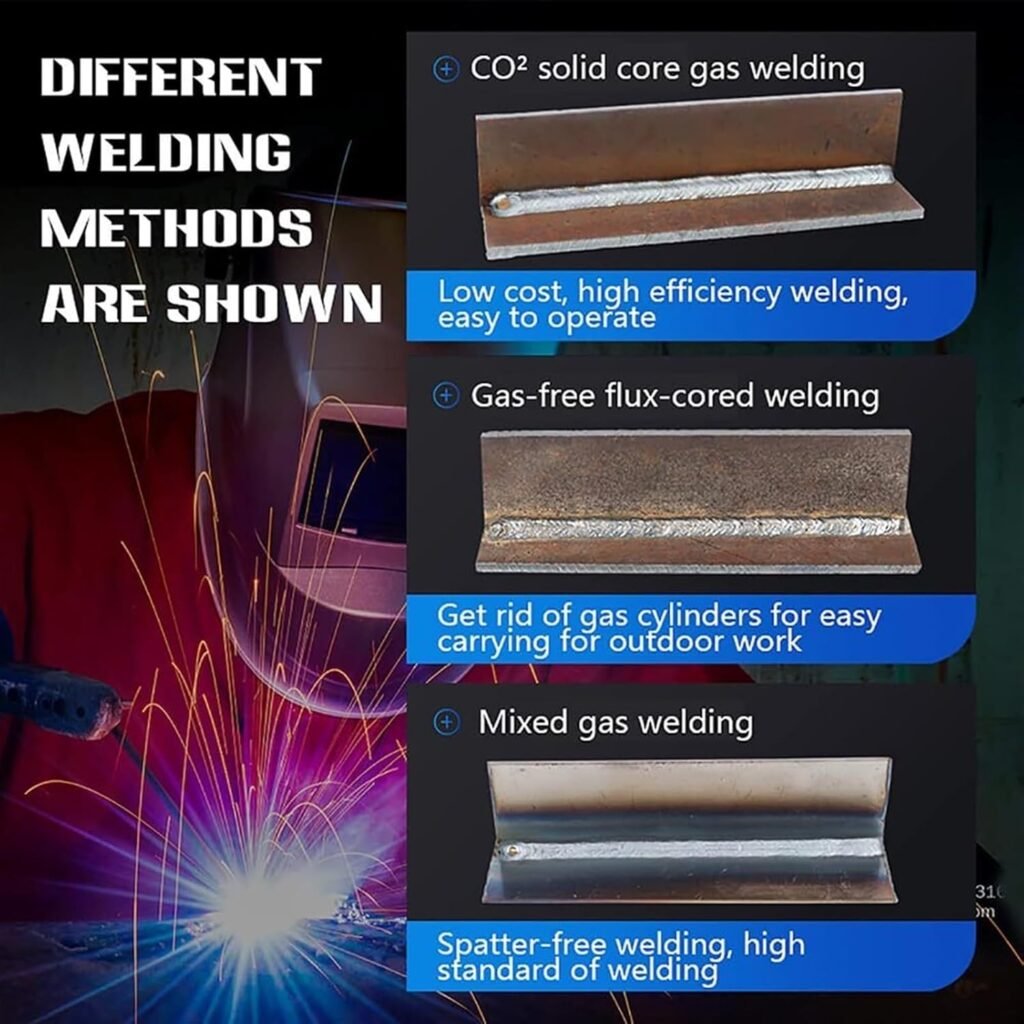

This welding machine combines MIG, MMA, and TIG modes in a compact package intended for mixed gas welding, gasless flux-core welding, and solid wire welding. It includes an intelligent One-Knob control that automatically adjusts welding current and wire feed for more consistent results, and it’s built with a high-strength metal body and a comfortable carrying handle for portability.

What the machine promises you

The manufacturer positions this unit as a lightweight, multifunctional welder suitable for pipe work, automotive repair, construction, hobby metalwork, and general maintenance. It aims to support both gas-shielded MIG (requires argon) and gasless flux-core MIG, plus MMA and light TIG tasks, giving you flexibility across common welding jobs.

What’s in the box

You’ll typically find the main welding unit, a MIG torch with wire feed, a ground clamp and cable, an electrode holder for MMA, a TIG torch or TIG adapter depending on the bundle, and a user manual. Consumables like contact tips, a drive roller, and sometimes a small spool of flux-core wire may be included, but gas bottles and full accessory kits usually aren’t part of the standard package.

Key specifications at a glance

Below is a simple breakdown of the main features and what they mean for your work.

| Feature | What it means for you |

|---|---|

| Welding modes | MIG (gas and gasless flux-core), MMA (stick), TIG (light duty). You can switch between processes for different jobs. |

| Control system | One-Knob intelligent control. Simplifies setup by letting the machine adjust current and wire feed automatically. |

| Gasless welding | Supported with flux-core wire. Useful for outdoor welding and windy environments where shielding gas can be blown away. |

| Gas requirement | Argon required for proper TIG and some MIG operations. You’ll need to supply your own gas cylinder for these tasks. |

| Body and handle | High-strength metal housing and thick handle. Durable and easy to carry around for mobile work. |

| Safety features | Overload and overheat protection with automatic shutdown and fans. Offers protection for both you and the machine. |

| Portability | Lightweight and compact. Designed for easy transport to jobsites or for storage in small workshops. |

| Use cases | Automotive, building decoration, pipeline, mold repair, general manufacturing. Broad range of light-to-moderate tasks. |

Design and build quality

You’ll notice the unit uses a metal shell rather than cheaper plastic, which gives it a sturdier feel and better resistance to knocks during transport. The thick handle is comfortable to grip, so carrying the welder between work locations feels straightforward rather than awkward.

The front panel layout is simple and logically arranged so you can reach the One-Knob control, mode switch, and output connectors without fumbling. The compact footprint makes it easier to fit the welder into a crowded work van or on a small bench.

One-Knob intelligent control explained

This One-Knob system is intended to reduce the number of settings you need to tweak manually: by turning a single control, you adjust wire feed speed and current in a coordinated way. For you, this means fewer trial-and-error setups and quicker starts on new pieces of metal, especially when switching between materials or wire sizes.

The synergy aspect automatically compensates and adjusts welding current to match the feed rate, helping you maintain a steadier arc and cleaner bead appearance. If you’re new to welding, this feature can significantly shorten the learning curve while still letting you fine-tune by practicing.

MIG Mode: how it performs for you

When you use MIG mode with shielding gas, expect smooth, clean beads on thin to moderate thickness steel if you match wire size and gas correctly. The unit supports both solid wire with argon shielding (or appropriate mixes) and flux-core wires for gasless welding, which makes it flexible for indoor and outdoor use.

Because this is a compact multi-process unit, it won’t outperform a full-size industrial MIG welder on very thick plate or in high-duty-cycle production work. For light fabrication, auto body repair, and general workshop tasks, it will deliver good results when you dial in settings appropriate to the metal and joint.

MMA (Stick) Mode: what you can do

Stick welding (MMA) is a valuable addition because you can weld with common stick rods in situations where gas isn’t available. This is handy for quick repairs on farm equipment, outdoor structural touchups, or where surface conditions are less than ideal.

You’ll get the usual stick benefits: tolerance for dirt or rust on the workpiece and suitability for thicker sections than a small TIG might handle. Keep your expectations reasonable for electrode sizes and the unit’s amperage limits—performance is best with light-to-medium electrodes typically up to 3.2 mm.

TIG Mode: light TIG capability

TIG mode on this machine is primarily intended for light TIG work and may require additional accessories depending on configuration. You can perform tack welding, thin-sheet welding, and finishing touches on projects where a fine, precise arc is needed.

Because it’s a multi-process machine, TIG on this unit won’t replace a dedicated high-performance TIG welder, especially if you need AC for aluminum or very high current for thicker sections. For steel and stainless on thinner materials or for occasional TIG needs, it gives you an extra tool in your kit.

Synergy and performance overview

Synergy—meaning the automated coordination of wire feed and current—helps you produce consistent beads faster by removing some manual adjustments. For your projects, synergy minimizes burn-through on thin materials and reduces spatter when welding with flux-core wires.

Performance will be good for hobbyists, DIYers, and light professional use. If you intend to run long, continuous welds on heavy sections, you’ll notice thermal limits and duty cycle constraints compared with larger single-process machines.

Gasless flux-core welding: practical benefits

Gasless welding with flux-core wire is one of the unit’s standout conveniences: you don’t need cylinders or regulators, so setup is quicker and you can work in windy conditions without losing shielding gas. This makes it ideal for outdoor repair work, farm use, and situations where you don’t want to haul gas bottles.

Remember that flux-core welding tends to produce more smoke and slag than gas-shielded MIG, so you’ll need to clean welds and ventilate properly. For structural or cosmetic work that demands a clean finish, gas-shielded MIG or TIG may still be preferable.

Safety features and protections

The unit has overload and overheat protection that will automatically shut the machine down if the temperature or voltage/current goes out of safe ranges. This protects both you and the electronics inside, helping prevent failures from sustained heavy use or electrical anomalies.

Active fans assist cooling while the machine is in operation. It’s still important that you allow the unit to rest if it heats up, and to keep vents clear of debris or accumulation of metal dust that could obstruct airflow.

Portability and handling

The compact design and sturdy handle make it easy for you to transport the welder between job sites or store it when not in use. If you often move around on a site or work remotely, this machine feels much less like a burden than bigger shop-only welders.

Because it’s relatively lightweight, you won’t need special lifting gear for short-distance moves, but be mindful of holding the torch upright and protecting hoses and cables from snags during transport.

Cooling and duty cycle considerations

This machine uses internal fans for cooling and has a duty cycle that limits continuous welding time to prevent overheating. For typical hobby and light professional tasks, the duty cycle will be reasonable, but for long production runs or thick-plate welding you’ll need to plan pauses to avoid thermal shutdown.

Watch for the thermal indicator lights and be ready to give the unit time to cool; forcing it past duty cycle limits will trigger automatic shutdown and shorten component life if repeated excessively.

Ease of setup and first use

You’ll appreciate the simplified setup: connect the power, wire spool, ground clamp, and torch, then select the welding mode and use the One-Knob to get you into the ballpark of proper parameters. For MIG gas-shielded welding, attach your argon cylinder and regulator; for gasless, load flux-core wire and skip the gas.

If you’re new to welding, take a few practice runs on scrap metal to adjust your technique and verify settings. The intelligent control reduces guesswork, but basic prep—cleaning metal, correct wire selection, and proper ground—still makes a big difference.

Accessories and consumables you’ll need

You’ll need welding wire (flux-core or solid), contact tips and a drive roller suited to the wire diameter, MMA rods, and TIG consumables like a gas cup and tungsten if you plan to TIG. For gas-shielded operations, an argon tank, regulator, and appropriate hose are required.

Optional but recommended items include a helmet with auto-darkening, gloves, welding jacket or apron, chipping hammer and wire brush for slag removal, and filler rods for TIG. Stocking the right consumables will save you downtime.

Typical applications and suitability

The machine suits car body repair, light fabrication, maintenance, building decoration, bicycle frame repairs, and small pipeline or structural touchups. If you mainly work on thin materials or need portability for outdoor jobs, this unit is particularly useful.

For heavy fabrication, high-production welding, or specialized TIG tasks like high-precision aluminum welding requiring AC output, consider a dedicated machine built for those demands. For general-purpose, mixed-process work, it is a cost-effective and flexible option.

Pros

- Multiprocess flexibility lets you handle MIG, MMA, and TIG tasks without buying separate machines. This saves space and initial investment while offering versatility.

- One-Knob intelligent control simplifies setup and shortens the learning curve for beginners. You’ll spend less time tuning and more time welding.

- Gasless flux-core capability is ideal for outdoor work and windy conditions where shielding gas would be impractical. You can start repairs faster without hauling gas.

- Robust metal housing and a comfortable handle make it durable and easy to transport between jobs. The build quality addresses common portability concerns.

- Overload and overheat protections keep both you and the machine safer during heavier use and prevent immediate component damage.

Cons

- As a compact multi-process unit, it won’t match the duty cycle or raw output of dedicated industrial MIG or TIG welders for prolonged heavy work. You’ll need to manage expectations on thick plate welding and continuous runs.

- TIG capability tends to be lighter-duty and may lack advanced TIG controls (like AC for aluminum), so it’s not a replacement for a full-feature TIG machine if you need frequent aluminum welding.

- Consumables and optional items like argon tanks, regulators, and high-quality torches may not be included, so add these to budget if you plan to use gas-shielded MIG or TIG.

- Flux-core welding produces more smoke and slag, so you’ll need to account for cleanup and ventilation when working indoors.

How this unit compares to similar welders

Compared to single-process hobby welders, this one wins on versatility because you don’t have to buy separate machines for MIG, MMA, and TIG. Against dedicated industrial machines, it’s more affordable and portable but sacrifices duty cycle and specialized features.

If you’re deciding between a compact multiprocess welder and a larger single-process unit, think about your regular workload: choose this combo for broad capability and portability; pick a single-process industrial welder if you need sustained high-current performance.

Tips for getting the best results

- Always clean the joint area before welding to reduce contamination and porosity in the bead. Even flux-core welding performs better on clean surfaces.

- Match wire diameter and welding mode to material thickness; too large a wire or too high a feed rate increases spatter and can cause burn-through on thin sheets.

- For gas-shielded MIG and TIG, use a fresh, correctly regulated argon supply and check connections for leaks. Proper shielding gas coverage is essential for good welds.

- Run practice beads on scrap before moving to the final workpiece to fine-tune knob settings for travel speed, angle, and arc length. The One-Knob helps, but your technique matters.

- Monitor the duty cycle and allow cooling periods to preserve the machine’s components and avoid forced shutdowns during critical jobs.

Maintenance and care

Keep vents and the fan area clear of dust and metal shavings to ensure proper cooling and prolong component life. Periodically check and replace consumables like contact tips, nozzles, and drive rollers to maintain wire feed performance and arc stability.

Store the machine in a dry environment when not in use and disconnect gas bottles and hoses for safety during transport. Regular visual checks of cables, connectors, and the torch head will help catch wear before it becomes a failure.

Troubleshooting common issues

- If your wire feed is inconsistent, check the drive roller pressure and alignment, and verify the spool and liner are compatible with the wire diameter. Also inspect the contact tip for wear or clogging.

- For porosity or poor bead appearance during gas-shielded MIG, confirm your gas flow rate, regulator setting, and check for leaks or drafts that might disturb the shielding.

- If the unit overheats and shuts down, reduce continuous welding time, allow adequate cooling, and make sure the fan vents are unobstructed. Excessive ambient temperature or dust buildup may also cause thermal trips.

Who should consider buying this machine

You should consider this welder if you’re a DIY enthusiast, hobbyist, or light professional who needs a single compact tool to handle a variety of welding tasks around the home, shop, or outdoor job sites. It’s also a good choice if you value portability and the convenience of gasless welding for outdoor repairs.

If your work is high-volume, high-duty-cycle welding on heavy sections, or if you need advanced TIG features for thin aluminum work, a dedicated industrial welder would be a better fit.

Safety gear and setup checklist before you weld

- Always wear an auto-darkening helmet, flame-resistant gloves, and protective clothing to prevent burns and eye damage.

- Ensure you have proper ventilation or fume extraction, especially when flux-core or coated electrode welding creates more smoke and slag.

- Secure your workpiece with a reliable ground clamp and inspect cables for damage before energizing the machine.

- Confirm the correct polarity and drive roll setup for your chosen wire type to prevent feeding issues and reduce wear.

Budget considerations and long-term cost

Initial purchase cost for a compact multi-process unit is generally lower than buying three dedicated machines, making it an attractive option for limited budgets. Long-term costs include consumables, gas for MIG/TIG work, and potential upgrades to torches or regulators, so factor those in when comparing offerings.

If you expect to expand into heavier work later, consider whether it makes sense to start with a multi-process welder and later add a dedicated MIG or TIG machine as required.

Real-world scenarios where this machine shines

You’ll appreciate this welder for mobile repairs like farm equipment fixes, on-site structural touchups, and auto body patching where portability and gasless capability speed the job. It also performs well for weekend metal fabrications, art projects, and maintenance work where flexibility beats specialized power.

For example, if you’re doing a fence repair in a windy field, gasless flux-core MIG gets you welded up without hauling argon. If you switch to a small garage TIG job to join thin stainless pieces, the TIG mode gives you the control you need without having to buy a separate TIG unit.

Common questions you might have

- Does it come with argon and regulators? Typically no — you’ll need to purchase gas bottles and regulators separately for gas-shielded MIG and TIG.

- Can it weld aluminum? TIG may work on very thin aluminum with the right setup and gas, but the unit likely lacks AC output needed for most aluminum TIG applications; MIG aluminum welding requires a solid wire and a spool gun for best results.

- How long can you weld continuously? Duty cycle varies; expect limited continuous weld time compared to industrial machines and plan for cooling intervals during longer tasks.

Final recommendation

If you want a portable, user-friendly multiprocess welder that handles a broad mix of MIG (gas and gasless), MMA, and light TIG tasks, this model delivers a solid balance of convenience and capability. It’s especially well suited for hobbyists, mobile tradespeople, and anyone who needs flexibility and portability without the expense of multiple dedicated machines.

For serious shop production, high-duty-cycle welding, or specialized TIG work on aluminum, consider complementing this machine with a dedicated industrial unit as your workload grows. If your priorities are versatility, portability, and simplified setup with reliable safety features, this 3-in-1 welder will likely meet your needs well.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.