Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a compact, budget-friendly conical shroud to improve your MIG welding setup without replacing your entire torch kit?

Quick first impression

You’ll notice immediately that the Mini Conical Nozzle Shroud Binzel Style Welding Welder MIG Gas Screw On 5PK is small, lightweight, and built to be an economical replacement or spare part. The first few minutes of handling give you a sense that it’s made for convenience and quick swaps, not heavy-duty industrial abuse.

What this product aims to do for you

This shroud is designed to sit over the MIG contact tip and direct shielding gas to the weld puddle while protecting the tip from spatter and damage. You get five identical pieces in the pack, which is handy if you work frequently or want spares on hand.

Product details and specifications

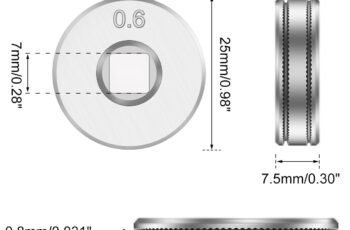

You should be clear about the core numbers before you buy, because size and thread compatibility are the two most important factors. The main specs are compact and will determine whether it fits your torch.

Core specifications explained

These specs tell you the physical fit and thread type, which govern compatibility with your torch. If you mismatch these values, it may not seat properly or could leak gas.

| Attribute | Value |

|---|---|

| Product Name | Mini Conical Nozzle Shroud Binzel Style Welding Welder MIG Gas Screw On 5PK |

| Shroud Type | Mini Conical |

| Compatibility | Suitable for use with standard torches (Binzel style) |

| Shroud Length | 38 mm |

| Thread Type | M8 (8 mm thread) |

| Outer Diameter | 15 mm |

| Quantity | 5 pieces per pack |

| Material | (Typically brass/plated steel or copper — check seller for exact metal) |

| Primary Use | Shielding gas direction and contact tip protection |

How to interpret the numbers

The length and diameter tell you how far the shroud extends past the contact tip and how much gas coverage you’ll get. The M8 thread is the most critical: if your torch has an M8-compatible gas lens or nozzle base, these will screw on cleanly.

Compatibility and fit

You’ll want to know whether this shroud will fit your torch without forcing anything. Compatibility is the make-or-break factor for a screw-on shroud.

Binzel style and standard torch fit

The name says “Binzel style,” which references a very common thread and seating design in many MIG torches. If your torch is based on Binzel-style consumables, these should thread on fine. You’ll still want to check the specific M8 thread and 15 mm outer diameter before buying.

How to check compatibility with your torch

You should measure the thread or consult your torch’s consumable chart. If you already use M8 threaded nozzles or have an adapter that accepts 15 mm outer diameter nozzles, the fit will likely be good. If you’re unsure, remove an existing nozzle and compare thread pitch and outer diameter visually.

Build quality and materials

While you won’t get aerospace-grade metallurgy from a budget pack, build quality affects durability, cleaning frequency, and how long the shroud lasts under regular use.

What the shroud is likely made of

Most mini shrouds of this type are made from brass, plated steel, or a copper alloy, offering decent thermal conductivity and moderate resistance to spatter. You should treat them as consumable items: they’re replaceable, not permanent fixtures.

Feel and finish in daily use

You’ll notice a smooth exterior finish and consistent thread machining on a decent batch. Thread quality matters because cross-threading ruins a nozzle quickly; these generally have acceptable thread definition for routine use.

Installation and removal

You’ll swap these often, so you should know how straightforward the process will be.

Step-by-step installation

You simply screw the shroud onto the M8 threaded gas diffuser or nozzle base until it seats firmly. Avoid over-tightening, since the shroud is small and cheap replacement is easier than trying to repair a stripped thread.

Removing the shroud without damaging threads

Hold the torch securely and unscrew by hand; if it’s stuck, use a small wrench carefully to avoid marring the surface. Applying a small amount of penetrating lubricant before full cool-down can help prevent seizing after heavy use.

Performance and weld quality

Performance is what matters most. You want consistent shielding gas coverage and minimal turbulence around the arc.

Gas coverage and shielding consistency

Because this is a mini conical shroud (38 mm length and 15 mm outer diameter), you’ll find it provides a focused gas stream aimed at the puddle. The result is usually good shielding for thin to medium sheet metal work and small joints. For wide beads or heavy fillet welds you might notice the coverage is more concentrated, so positioning matters.

How it affects arc stability and spatter control

You should see comparable arc stability to other short conical nozzles. The shroud helps reduce spatter impact on the contact tip, which means fewer stoppages for cleaning and less frequent tip replacement. On the flip side, since the gas cone is narrower than larger nozzles, you might get a little more sensitivity to travel angle and distance.

Use cases and performance on different materials

Different materials mean different gas flows and bead appearance. Knowing where this nozzle shines helps you decide if it fits your projects.

Thin sheet metal and light fabrication

You’ll get excellent results on thin steel up to about 1/8″ (3 mm) with the right wire and gas. The focused gas cone helps produce clean, narrow beads with minimal burn-through risk.

Medium-thickness work and light structural welding

For medium thickness steel, you’ll still be fine for tack welds, small fillets, and repairs. You should pay attention to travel speed and electrode stick-out to keep gas coverage effective.

Stainless steel and aluminum considerations

For stainless, you’ll want the correct shielding gas (e.g., argon/CO2 mix or 100% CO2 depending on process) and mindful technique; the shroud won’t make up for wrong gas. For aluminum MIG, Beware that aluminum requires larger nozzle and special contact tips; this small conical shroud is generally not recommended for heavy aluminum work without checking fit and gas flow.

Thermal behavior and durability

Heat is the enemy of consumables; you should understand how these hold up under sustained welding.

Heat dissipation and thermal limits

The small size means less mass to absorb and dissipate heat, so they heat up quickly. For intermittent short runs and repair work you’ll be fine, but if you run long continuous beads at high amps, expect faster discoloration and more frequent replacement.

Resistance to spatter and deformation

These shrouds protect contact tips from direct spatter fairly well, but repeated heavy spatter will still pit the nozzle and require cleaning. You should remove and chip away heavy spatter rather than letting it accumulate.

Cleaning, maintenance, and replacement cadence

Since these are consumables, you’ll maintain them to maximize life and performance.

Routine cleaning tips

You should remove spatter regularly with a nozzle reamer, pick, or light grinding if necessary. Avoid aggressive grinding that changes the taper; a wire brush and occasional soak in a nozzle cleaner help.

When to replace them

Replace the shroud if the inner taper is deformed, threads are damaged, or gas leakage occurs. With regular hobby use you might change them monthly; in a production environment you could be changing them weekly or even daily depending on spatter.

Practical tips for getting the best results

A few technique changes will make a big difference in how these perform for you.

Optimize contact tip protrusion

You should maintain consistent stick-out (contact tip protrusion) appropriate for your wire diameter — typically 10-15 mm for many MIG setups. This helps ensure consistent arc and gas shielding within the narrow cone the mini shroud provides.

Adjust welding angle and travel speed

Because the gas cone is focused, you’ll get best results when you keep your gun angle close to perpendicular or with a slight push. Keep steady travel speed to avoid pulling too much heat or exposing the puddle outside gas coverage.

Pros and cons summarized

When you’re weighing a purchase, you want clarity on strengths and trade-offs.

Pros

- You get five pieces, so you won’t run out quickly and have backups ready.

- Compact size gives focused gas coverage, which helps with narrow beads and thin materials.

- M8 thread and 15 mm outer diameter make it compatible with many Binzel-style torches.

- Affordable replacement parts—economical for hobbyists and small shops.

Cons

- Small shroud means limited gas coverage for large welds or wide fillets.

- Heat buildup occurs faster compared to larger nozzles, shortening life in heavy use.

- Material specifics may vary by seller; check for brass vs. plated steel if you require a particular metal.

- Not ideal for heavy aluminum MIG without ensuring correct size and tip compatibility.

Comparison with other nozzle styles

You should pick the right nozzle for your job. Here’s how the mini conical stacks up.

Mini conical vs. standard cylindrical nozzles

Compared to cylindrical nozzles, the mini conical is more focused and offers less lateral gas spread. You’ll trade off breadth of coverage for a tighter gas cone that helps on precision work.

Mini conical vs. larger conical nozzles

A larger conical nozzle gives broader gas coverage and handles more heat, making it preferable for heavier work. You should choose the mini conical for fine work, not heavy continuous bead work.

Who should buy this product

If your work profile matches these descriptions, this pack makes sense for you.

Ideal users

You should consider this if you do light fabrication, automotive body repairs, hobby projects, or small repairs where compact shielding is helpful. The 5-pack makes it attractive if you like to have spares ready without frequent reordering.

Who should avoid it

You should probably avoid this if you do heavy industrial welding every day, large structural welds, or extensive aluminum MIG without confirming fit and coverage needs. For high-amperage or long, continuous welds, a larger, more heat-tolerant nozzle is preferable.

How to install for optimal gas coverage (step-by-step)

You should be able to install these quickly and get consistent shielding.

Step 1: Inspect the mating threads

Check the gas diffuser or nozzle base for burrs and old spatter; clean before threading to prevent cross-threading. You want a smooth mating surface.

Step 2: Hand-start the thread

Screw the shroud on by hand initially to avoid cross-threading, then tighten snugly without forcing it. Proper seating helps prevent gas leakage.

Step 3: Check alignment and tip protrusion

Verify that the contact tip protrusion is correct and that the shroud doesn’t contact the tip. Adjust the tip if needed to maintain recommended stick-out.

Troubleshooting common issues

You’ll encounter some recurring issues over time; here’s how to handle them.

Poor gas coverage or porosity in welds

If you see porosity, verify gas flow, check for drafts, and confirm the shroud and diffuser threads are sealed. Also confirm the nozzle isn’t deformed; replace if necessary.

Shroud seizes or becomes very tight

If the shroud won’t unscrew, apply penetrating oil once cooled and use a small torque tool. Avoid excessive heat—cool down before attempting major force to prevent thread damage.

Excessive spatter buildup

If spatter builds up quickly, reduce wire stick-out, clean contact tips and nozzle more often, and check welding parameters for excessive voltage or incorrect polarity.

Value and pricing considerations

You’ll evaluate price relative to frequency of replacement and the convenience of having spares.

Is the 5-pack worth it?

For hobbyists and small shops, a 5-pack is practical and cost-effective. You’ll usually save money vs buying individual nozzles and have replacements ready to reduce downtime.

How to judge seller claims and material

You should always verify the seller’s material specification if you need particular conductivity or thermal behavior. Brass and copper variants differ in cost and thermal properties; choose according to your priorities.

Alternatives and complementary consumables

You should consider what else you might need to pair with these nozzles for an effective setup.

Gas lenses and diffusers

If you need greater gas coverage and better shielding, using a gas lens or a larger diffuser with compatible thread can help. Make sure thread types match before switching.

Contact tips and liners

Complement with high-quality contact tips matching your wire diameter, and check your liner condition to ensure consistent wire feed. Replacing tips when you replace nozzles is common maintenance practice.

Safety reminders

You’ll want to keep safety front and center when installing or changing consumables.

Basic precautions

Always switch off welding power and disable the wire feed before changing nozzles. Allow the torch to cool and wear gloves to avoid burns.

Handling and storage

Store spare shrouds in a dry place to avoid corrosion. Keep them in a labeled container so you can quickly grab the correct M8-threaded size when needed.

Final verdict and buying recommendation

If you need compact nozzles that are affordable and compatible with Binzel-style M8-threaded torches, you’ll find the Mini Conical Nozzle Shroud Binzel Style Welding Welder MIG Gas Screw On 5PK to be a practical choice. It’s ideal for repair work, thin metal work, and situations where you want focused gas coverage and easy spare availability.

When to buy this product

Buy this if your torch uses M8 threaded consumables, you want multiple spares for convenience, and your welding tasks mostly involve thin to medium material sizes. Avoid it only if you require broad gas coverage for large fillets or heavy continuous welding.

Frequently asked questions (FAQ)

You’ll want quick answers before your next purchase—here are the most common ones.

Will this fit my torch?

Check your torch’s consumable chart or measure the thread; if it’s M8 and your current nozzle outer diameter is around 15 mm, you’re likely compatible.

Can I use these for aluminum?

You should be careful: aluminum MIG often needs different contact tips and larger nozzles. Confirm fit and gas requirements before using these for aluminum work.

How often will I need to replace them?

Replacement frequency depends on use and spatter. As a rule of thumb, frequent hobby use may require monthly replacement, while a production shop might need to replace them much more often.

Are these genuine Binzel parts?

These are Binzel-style and compatible, but unless specified by the seller as OEM Binzel branded parts, they’re likely third-party compatible consumables. Check the product listing for exact manufacturer claims.

Maintenance checklist you should follow

A short checklist helps you keep your torch running well with these shrouds installed.

- Inspect and clean shroud and diffuser before and after each welding session.

- Keep spare nozzles in a labeled container for quick swaps.

- Replace contact tips with the nozzle if you notice poor feed or wobble.

- Check gas flow and torch alignment before critical welds.

Closing note on usability

You’ll find this 5-pack to be a sensible, low-cost way to keep your MIG torch ready for frequent or intermittent work. The Mini Conical Nozzle Shroud Binzel Style Welding Welder MIG Gas Screw On 5PK gives you a combination of compatibility, focused gas shielding, and a practical spare count—useful for hobbyists and small shops who want dependable, replaceable parts without high cost.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.