Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you trying to find a reliable regulator that will keep your MIG and TIG welding gas flowing smoothly and safely?

Quick Product Overview

You want gear that’s dependable and simple to use, and the RX Weld argon regulators Gauges Gas Welding, Regulator for MIG and TIG, CGA580 Inlet Connection aims to deliver exactly that. This regulator is meant for common inert and shielding gases, has a solid brass body, and ships with a hose so you can get set up quickly.

What this product is

You’re looking at a single-stage pressure regulator and flowmeter designed for argon, helium, and CO2 use on welding rigs. It pairs with tanks that use a CGA-580 inlet connection, which is the typical fitting for many inert gas cylinders used in MIG and TIG setups.

Key specifications

You need clear numbers so you can confirm compatibility with your equipment. Below is a breakdown of the most important specifications so you can verify fit and performance at a glance.

| Specification | Details |

|---|---|

| Product name | RX Weld Argon Regulators Gauges Gas Welding, Regulator for MIG and TIG, CGA580 Inlet Connection |

| Compatible gases | Argon, Helium, CO2 |

| Inlet connector | CGA-580 (tank connector) |

| Outlet connectors | 9/16″ male, 5/8″ female |

| Inlet pressure range | 0–4500 PSI |

| Delivery flow/pressure range | 0–40 CFH (cubic feet per hour) |

| Body material | Brass |

| Packing / Included items | 1 x argon regulator, 1 x 6.6 feet hose |

| Intended use | MIG and TIG welding, laboratory and light industrial shield gas delivery |

You can use these specs to confirm that the regulator matches your cylinder valve and that the flow range meets your welding needs. The brass body helps with durability and resistance to corrosion from inert gases.

Design and Build Quality

You will immediately notice the brass body and sturdy construction, which helps with longevity and adds a premium feel compared to plastic regulators. The gauge faces and adjustment knobs are laid out for straightforward operation so you won’t have to struggle during setup.

Materials and construction

You’ll appreciate that brass is used for the main body, because brass resists corrosion and handles typical welding gas service well. The gauges are usually glass or polycarbonate-covered with clear markings so you can read pressure reliably.

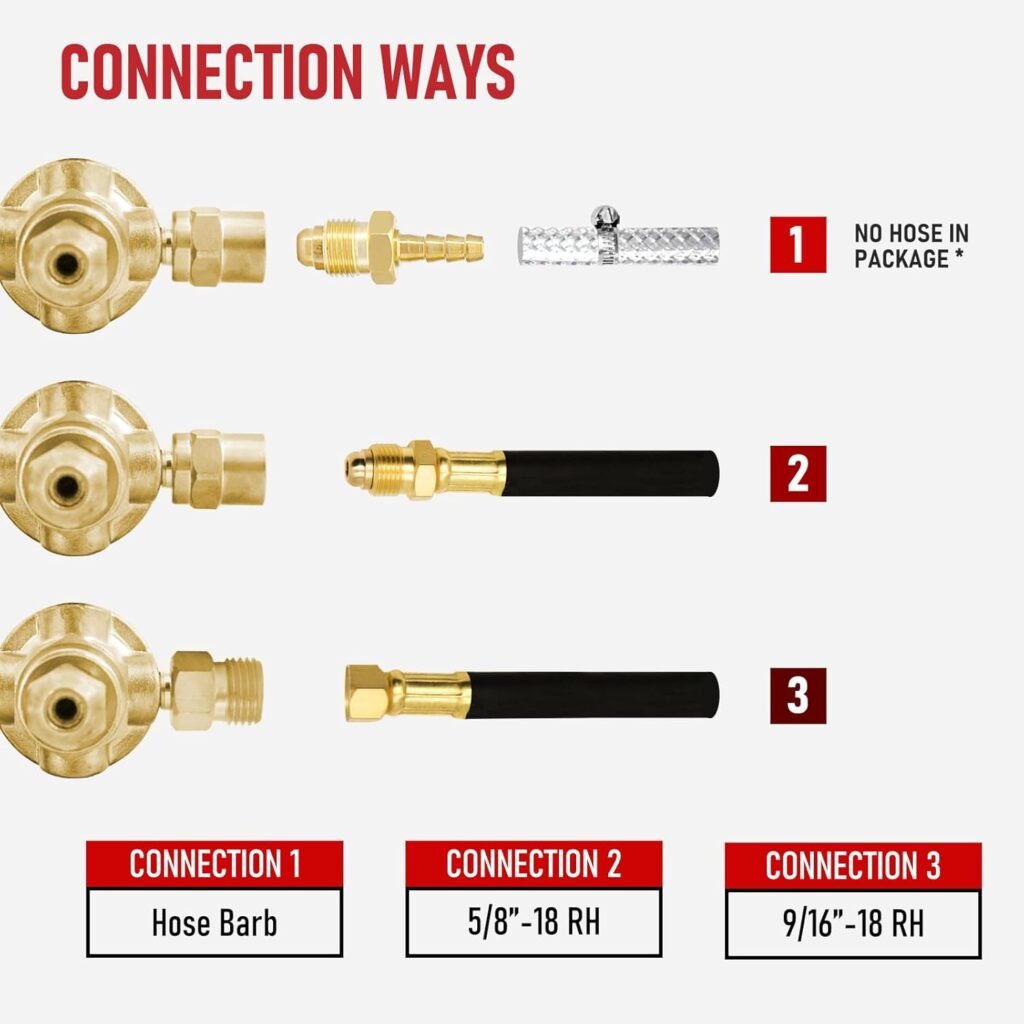

Inlet and outlet connectors

You need the right fittings to hook up without adapters, and the CGA-580 inlet ensures compatibility with many argon and helium tanks. On the outlet side, having both 9/16″ male and 5/8″ female connectors gives you flexibility with hoses and torch fittings commonly found in welding setups.

Performance with MIG and TIG

You want stable, predictable flow whether you’re welding with MIG or TIG, and this regulator is built to provide consistent delivery in the 0–40 CFH range. That flow range covers typical TIG and most MIG shielding gas needs for hobby and light professional use.

Flow control and pressure range

You’ll find the delivery pressure and flow range adequate for most welding tasks; 0–40 CFH gives you fine control for TIG and sufficient flow for MIG at typical settings. The inlet side accepts pressures up to 4500 PSI, which is standard for full gas cylinders, ensuring the regulator can handle the full tank pressure safely.

Real-world usability

You’ll notice the regulator’s adjustment knob is intuitive to use, helping you set exact flows and maintain them while welding. For steady, long welds you’ll benefit from consistent output, and the included hose simplifies immediate setup so you can start welding without chasing parts.

Installation and setup

You want setup to be fast and foolproof, and the regulator’s CGA-580 inlet makes mating to common cylinder valves straightforward. The included 6.6-foot hose gives you a practical reach to your torch and bench, reducing the need for additional hose purchases.

Connecting to tanks

You’ll attach the regulator to the tank with the CGA-580 inlet, and it’s important to hand-tighten and then make a final snug fit with a wrench—without over-tightening—to prevent leaks. Always check threads and sealing surfaces for damage, and open the cylinder valve slowly while watching the gauges to ensure normal pressurization.

Hose and fittings

You’ll like that a 6.6-foot hose is included, which typically covers small shop layouts and hobby benches. Make sure the hose ends match your torch and regulator outlet fittings; adapters may be needed if your torch uses different fittings than the 9/16″ male or 5/8″ female options provided.

Accuracy and gauge readability

You want to trust the numbers you see on the gauge when setting up gas flow, and this regulator typically features clear, readable gauges. The face markings should allow you to set and confirm pressure and tank content fairly accurately for general welding needs.

Gauge face and calibration

You’ll probably find the gauges easy to read, supplied with standard PSI and possibly flow markings. Keep in mind that many affordable regulators are not precision-calibrated for lab-level accuracy, but they are suitable for welding where repeatable and stable settings matter more than laboratory-grade precision.

Stabilizing pressure and leaks

You’ll want the regulator to settle quickly and hold pressure during welding. Most users should get steady downstream pressure so you can maintain consistent arcs. If you see fluctuations, check connections, tighten fittings, and inspect the diaphragm or seals for wear if performance is consistently poor.

Safety features and precautions

You care about safety, and this regulator’s brass construction and standard fitting sizes help provide a safe, standard connection to your gas cylinder. It’s crucial to follow safe practices when installing, operating, and storing pressure regulators.

Overpressure protection and compatible gases

You’ll be using it with argon, helium, or CO2, which are compatible with the regulator’s materials and design. Still, never use oxygen or combustible gases unless a regulator is specifically rated for them. The inlet range to 4500 PSI is typical, but you should always open cylinder valves slowly and keep the regulator’s outlet set within safe operating ranges.

Maintenance tips for safety

You’ll want to inspect seals, gauges, and the hose regularly for signs of wear or damage. Replace worn or cracked hoses, ensure fittings remain tight, and keep oil, grease, and other contaminants away from regulator and cylinder connections, especially when working with oxidizing gases like oxygen (which this regulator is not intended for).

Pros and Cons

You need a quick summary so you can decide if this regulator fits your needs, and below are straightforward advantages and trade-offs to expect when choosing this model.

Pros

- Compatible with argon, helium, and CO2, which covers the most common welding gases you’ll use.

- CGA-580 inlet ensures easy fit to many inert gas cylinders without exotic adapters.

- Brass body offers durability and corrosion resistance, improving service life in workshop conditions.

- Includes a 6.6-foot hose so you can start using it sooner without additional purchases.

- Flow range of 0–40 CFH provides adequate control for both TIG precision and MIG coverage.

- Outlet connector options (9/16″ male, 5/8″ female) add flexibility for torch and hose compatibility.

Cons

- Single-stage regulators can allow more fluctuation as tank pressure drops compared to two-stage units, which matters on long runs or critical gas-sensitive processes.

- Not marketed as a precision calibration device, so if you need lab-level accuracy you may need a higher-grade regulator.

- If your torch or hose uses uncommon fittings, you may still need adapters despite the included connectors.

- There’s limited documentation or advanced features like pulse flow control; this is a practical, straightforward unit rather than a feature-rich electronic controller.

Comparison with similar regulators

You want to know how this model stacks up against other options, whether you’re comparing to budget units or higher-end industrial regulators. It holds its own where simplicity, price, and compatibility are priorities.

Against cheap generic regulators

You’ll find this regulator generally better constructed than the cheapest plastic-bodied units and often has clearer gauges and a more robust brass body. Cheap regulators can have plastic components and less durable seals, which can mean shorter life and less stable performance.

Against premium industrial regulators

You’ll notice premium industrial regulators often offer two-stage regulation, finer flow control, superior calibration, and sometimes more rugged certifications. You’ll get fewer bells and whistles with this RX Weld model, but also a lower price and still solid performance for most welding needs.

Who this is best for

You want to pick gear that matches your skill level and usage, and this regulator suits multiple types of users depending on needs and expectations.

Hobbyists and small shops

You’ll appreciate the included hose, reasonable flow range, and straightforward connection if you run a home shop or small repair business. The regulator’s ease of use and typical compatibility make it a great value for hobbyists and light professional users.

Professionals and heavy users

You’ll find it works well for many pro applications, but if your workflow demands ultra-stable pressure under long tank draw-downs or very precise flow repeatability, you might prefer a two-stage industrial regulator. That said, it still performs adequately for many professional welding tasks where convenience and cost-effectiveness matter.

Troubleshooting common issues

You want solutions when things don’t work as expected, and the most common issues center on leaks, gauge reading problems, and fitting mismatches. Below are practical steps to identify and remedy typical problems so you can get back to welding quickly.

Leaking connections

You’ll first check all threaded connections and hose clamps for snugness. Use a soapy water solution to check for bubbles at fittings; bubbles indicate leaks. If leaks persist, replace seals or O-rings and confirm threads aren’t cross-threaded or damaged.

Gauge not reading or drifting

You’ll check for obvious damage to the gauge face and ensure the gauge is seated and tightened properly. If the gauge drifts slowly, the internal sensing element or diaphragm could be failing, and replacing the gauge or the regulator may be required if recalibration doesn’t fix the issue.

Maintenance and care

You want the regulator to last, and routine maintenance will extend its reliable service life. Regular checks, careful storage, and replacing consumable parts at the first sign of wear will keep gas delivery steady and safe.

Regular checks and cleaning

You’ll inspect gauges, seals, and hose integrity before each use and clean any dirt or debris from the exterior. If buildup or corrosion appears, gently clean with appropriate solvents and inspect seals; replace O-rings and washers at the first hint of cracking.

Storage and long-term care

You’ll store the regulator in a dry, dust-free place and keep the protective cap on the cylinder valve when the regulator is removed. If the regulator won’t be used for extended periods, depressurize it and keep it in a sealed bag or box to limit dust and moisture ingress.

Buying advice and value

You want to get the best match for your budget and needs, and this regulator provides solid value if your priorities are compatibility, decent flow range, and ease of setup. Consider what you actually need in terms of precision and long-term stability before deciding.

What to look for when buying

You’ll verify the inlet type (CGA-580) matches your cylinder valve, ensure the flow and pressure ranges suit your welding processes, and check that the outlet fittings will connect to your torch or that you can obtain inexpensive adapters. Also consider whether single-stage regulation is adequate, or whether a two-stage unit is worth the extra cost for your work.

Is it worth the price?

You’ll likely find this regulator represents a good balance of price and functionality for hobbyists, small shops, and many professional welders. If you require extreme precision or heavy industrial duty cycles, budget for a higher-spec unit; for most users, the RX Weld model will deliver strong value.

Frequently Asked Questions

You’ll naturally have questions, and below are some of the most common ones answered clearly so you can make an informed decision.

Can this regulator be used for oxygen or acetylene?

You shouldn’t use this regulator for oxygen, acetylene, or other gases unless the manufacturer explicitly rates it for those gases. This model is intended for inert and non-oxidizing gases like argon, helium, and CO2; using it with incompatible gases can be dangerous.

How do I know if the CGA-580 fits my tank?

You’ll visually inspect your tank valve for a CGA-580 marking or compare thread styles and size. CGA connectors are industry-standard: CGA-580 is specifically used for certain inert gases, so if your tank is for argon or helium it likely uses CGA-580.

How often should the regulator be serviced?

You’ll perform basic visual checks before each use and consider more thorough inspections annually or per shop safety protocols. If you weld daily or under harsh conditions, increase inspection frequency and replace wear parts sooner.

What if the regulator causes welding gas contamination?

You’ll isolate the source of contamination by checking hoses, fittings, and the regulator internals for oils, greases, or debris. Never use oil or grease near gas connections, and replace any suspect components immediately to prevent gas contamination.

Is the included hose compatible with my torch?

You’ll check the hose ends and torch fittings against the regulator’s outlets (9/16″ male, 5/8″ female). If fittings don’t match, low-cost adapters are available to bridge differences, but ensure adapter threads and materials are appropriate for welding gases.

Will this regulator maintain steady flow as the tank empties?

You’ll get stable flow for typical welding sessions, but single-stage regulators can show more downstream pressure change as tank pressure drops compared to two-stage regulators. For very long weld times or critical gas-sensitive tasks, consider a two-stage regulator for the most consistent output.

Can this regulator be used outdoors in cold weather?

You’ll use it in mild cold without special precautions, but very low temperatures can affect gauge readability and sealing materials. If you often work in freezing conditions, consider regulators and gauges rated for low-temperature operation.

Where to get spare parts like washers and gauges?

You’ll find generic replacement O-rings, washers, and gauges at welding supply stores or reputable online retailers. Always match material and size specifications to ensure compatibility and safety.

Final thoughts

You’ll find the RX Weld Argon Regulators Gauges Gas Welding, Regulator for MIG and TIG, CGA580 Inlet Connection to be a practical, cost-effective choice for many welders. It offers good compatibility, a useful flow range, and solid build quality for hobbyists and many professional settings, while still requiring the usual care and safety checks you’d expect for any gas-regulator setup.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.