Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you trying to decide whether the VEVOR Fiber Optic Welding Machine with 6 Motors, Core Alignment, Splicing Machine, 6s Splicing & 13s Heating, Fusion Splicer with 5 Inch Touch Screen, 3 in 1 Fiber Holder, 7800mAh Battery for SM MM DS is the right tool for your fiber work?

Overview

You’ll find that this VEVOR fusion splicer aims to balance fast field performance with a feature set that technicians normally expect from higher-end units. It combines six precision motors and core alignment to speed up splicing while promising low loss, a large touch display for easier inspection, and a robust battery so you can finish long jobs without hunting for a power outlet.

What the product promises

The main selling points are very fast splice times (6 seconds), rapid heating (13 seconds), very low fusion loss (manufacturer states 0.01 dB for multimode), and a 5-inch color touch screen with variable magnification up to 1100x. It also comes as a kit with tools and a portable bag so you can take everything to the field.

Who should consider this unit

If you perform frequent field splicing, work on both single-mode and multimode fibers, or need a compact machine that can handle a wide variety of fiber types (SM, MM, DS, NZDS, UI, BUI, EDF), this model is worth evaluating. You’ll especially appreciate the long battery life and rugged construction when you’re working outdoors or on long jobs.

Design and Build Quality

You’ll notice that the splicer uses ABS and PC materials on the exterior, which keeps the unit lightweight while helping it resist shocks and environmental wear. The housing is designed to be dustproof and shatterproof, so it’s ready for the typical knocks and bumps that come with fieldwork.

Portability and field use

Because the kit includes a portable bag that keeps accessories tidy, you can easily carry the entire setup to a job site. The 7800mAh battery means you can complete many splicing cycles on a single charge, reducing the need to bring extra battery packs or search for charging points mid-job.

Durability and environmental resistance

You can count on the unit holding up under different weather conditions and altitudes thanks to the sturdy shell. The dust and shock resistance helps protect internal optics and electronics, so you’ll spend less time on emergency repairs and more time on productive work.

Display and User Interface

The 5-inch color touch screen gives you an intuitive way to handle menus and view splices. The screen supports several display modes and offers magnification controls so you can inspect fiber cores visually and confirm alignment before committing to a splice.

Touchscreen responsiveness

The touchscreen is reported to be responsive and simple to operate, which helps you speed up your workflow. If you’re used to older non-touch splicers, you’ll likely find the touch-based controls more modern and faster for navigating settings.

Magnification and viewing modes

You’ll get an independent X or Y magnification display (330x) and can double-click to zoom to 1100x, plus a simultaneous 200x X/Y display for easy core alignment checks. These viewing options help you visually verify core alignment and cleanliness before splicing.

Splicing Performance

This VEVOR splicer uses six high-precision motors and core alignment to perform fast, accurate splices. The manufacturer states a splicing time of 6 seconds and a heating time of 13 seconds, which helps you move quickly through multiple splices during a job.

Speed and accuracy

Because of the six-motor configuration and core alignment system, you’ll experience consistent fiber positioning and faster cycle times compared with many 1–4 motor alternatives. Faster splicing times reduce downtime and allow you to finish larger jobs more quickly.

Fusion loss and splice quality

The claimed fusion loss is very low for multimode fiber—0.01 dB (MM)—which indicates a high-quality splice when using compatible fibers and proper technique. Keep in mind that actual loss will vary by fiber type, environmental conditions, cleave quality, and your process.

Heating and protection sleeve

In 13 seconds the unit reportedly completes heat-shrink protection, using included heat shrink tubes from the kit. Quick and consistent heating helps protect the splice joint while letting you get to the next task sooner.

Fiber Compatibility and Holders

You’ll appreciate the 3-in-1 fiber holder that supports SM (single-mode), MM (multimode), DS, NZDS, UI, BUI, and EDF fibers. That compatibility makes the unit versatile for a variety of fiber types you’ll encounter in telecommunications, CATV, and enterprise installations.

Adapter and holder flexibility

The 3-in-1 holder streamlines switching among common fiber types and reduces the time you spend changing adapters. If you move between single-mode and multiple multimode formats, you’ll find the holder configuration convenient for fast field changes.

Battery and Power

The built-in 7800mAh rechargeable battery gives you long on-site uptime. According to the product details, one full charge supports over 260 consecutive fusion splicing and heating cycles—helpful when you’re running long fiber runs or working in remote areas.

Working time and charging

Actual cycle count per charge will depend on usage patterns, screen brightness, frequency of heating cycles, and environmental temperature. The side USB port provides convenient charging and data transfer, so you can top up from portable power banks or connect to other devices as needed.

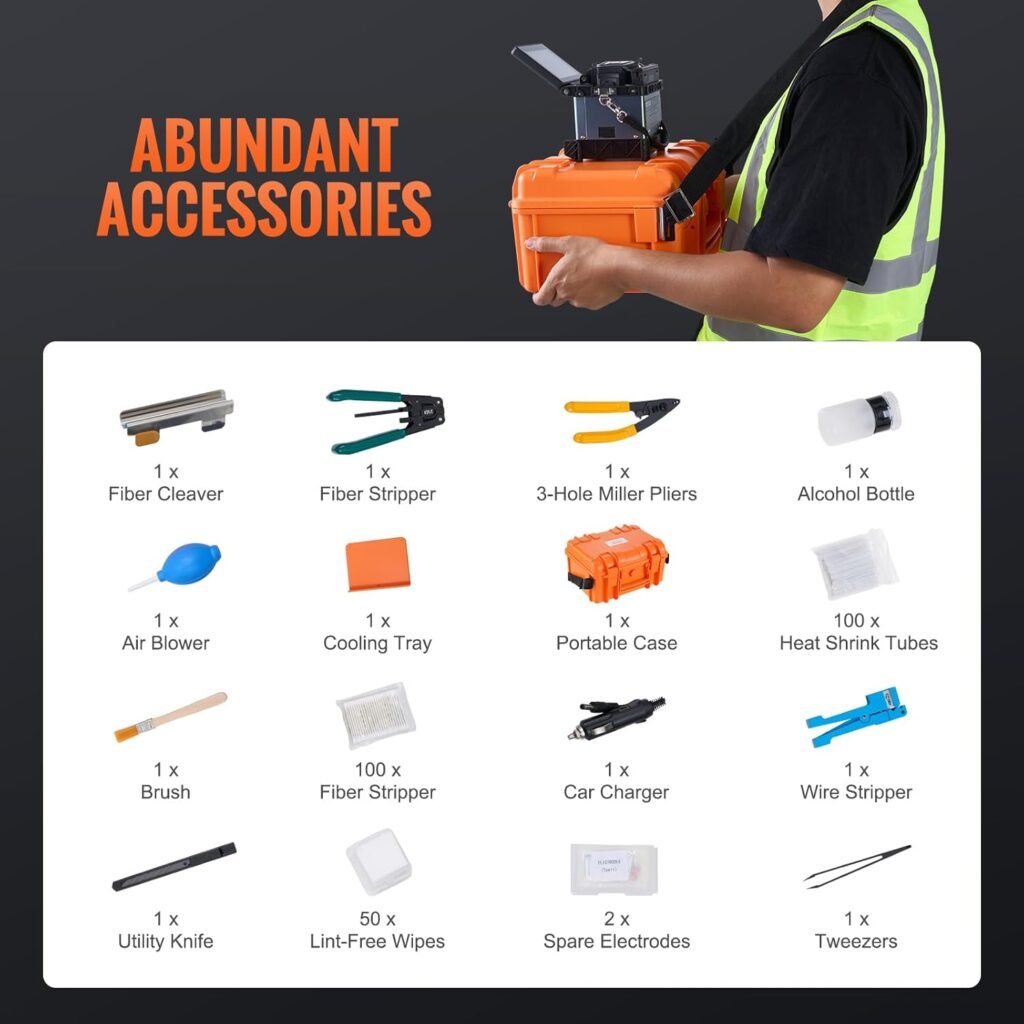

Professional All-in-One Kit

You won’t need to buy separate basic accessories for many jobs. The kit includes: the fusion splicer, fiber separator, fiber stripper, 3-hole router plier, alcohol bottle, air blower, cooling tray, heat shrink tubes, brush, cotton swabs, and other essential tools. The included bag keeps everything organized.

What’s included and how that helps your workflow

Having a complete kit means you can go straight to work without assembling missing tools. You’ll spend less time sourcing small items and more time on actual splicing tasks.

Technical Summary Table

Below is a concise table to help you quickly scan the technical highlights and what they mean to you.

| Feature | Specification / Detail | Why it matters to you |

|---|---|---|

| Product name | VEVOR Fiber Optic Welding Machine with 6 Motors, Core Alignment… | Full model name for identification |

| Motors | 6 high-precision motors | Faster and more accurate fiber alignment |

| Alignment | Core alignment | Better splice quality, especially for single-mode fiber |

| Splicing time | 6 seconds (typical) | Faster throughput on jobs |

| Heating time | 13 seconds | Quicker protective sleeve shrinking |

| Fusion loss (MM) | 0.01 dB (manufacturer claim) | Low loss for multimode splices |

| Display | 5-inch color touch screen | Easier visualization and settings control |

| Magnification | 330x independent; double-click to 1100x; 200x X/Y simultaneous | Clear core visualization for alignment |

| Battery | 7800mAh rechargeable | Long field runtime, >260 cycles (manufacturer claim) |

| Fiber compatibility | SM, MM, DS, NZDS, UI, BUI, EDF | Works with many fiber types |

| Holder | 3-in-1 fiber holder | Quick switching among fiber types |

| Materials | ABS + PC casing | Lightweight but durable |

| Kit items | Stripper, separator, plier, alcohol bottle, blower, heat shrink, etc. | Ready-for-field operations |

| Environmental resistance | Dustproof, shatterproof, shockproof | Rugged for field environments |

Setup and Daily Workflow

You’ll get the best results by following a consistent process: prepare the fiber (strip and clean), cleave precisely, load into the correct holder, check alignment on the screen, perform the splice, then heat shrink the protection sleeve and inspect the result. Keeping a steady routine reduces mistakes and improves splice quality.

Step-by-step suggestions for efficient work

- Verify the fiber type and install the appropriate holder.

- Strip the fiber jacket and clean thoroughly using alcohol and lint-free wipes.

- Cleave using a quality cleaver to produce a perpendicular end face.

- Place both fibers in the holder and use the touch screen to confirm alignment.

- Run a splice; after completion, perform the heating cycle with the included heat shrink.

- Inspect the splice visually and, if possible, test with an OTDR or insertion loss meter.

Practical tips to speed up repeat jobs

- Pre-prepare multiple fibers when you have a long run, so you only splice and heat in sequence.

- Keep spare electrodes and a cleaver in the kit to minimize downtime.

- Use consistent cleaning and cleaving techniques to reduce rework.

Maintenance and Care

Maintain electrodes, optics, and the cleaver to keep performance high. Regular cleaning and periodic electrode replacement will prevent inconsistent arcs and poor splices.

Electrode care and replacement

Electrodes wear with use and will need replacement occasionally; check your manual for the recommended intervals. If you notice higher loss or inconsistent arcs, check and replace electrodes as needed.

Cleaning optics and lenses

Use the included brush, blower, and lint-free swabs to keep lenses and the V-groove area clean. Dust and residue degrade performance and make alignment harder, so a quick clean between jobs is a good habit.

Troubleshooting Common Issues

If you encounter issues, most problems are solvable on-site. Below are common problems and sensible steps you can take.

High splice loss

- Confirm cleave quality and clean fiber ends.

- Reconfirm correct holder and alignment settings.

- Check electrode condition.

Splicer won’t power on or battery drains quickly

- Confirm battery is charged and inspect the charging cable.

- If battery life degrades over time, consider battery replacement or using external power during long jobs.

Failure to ignite arc or inconsistent arcs

- Clean electrodes and inspect for physical damage.

- Confirm environmental conditions (extreme cold or wind can affect arcs).

- Recalibrate and run a test arc per the manual.

Display or touchscreen problems

- Check for dirt or oil on the screen and clean gently.

- Restart the device; if problems persist, consult the manufacturer or service center.

Safety and Best Practices

Always handle fibers and tools safely. Use eye protection whenever cutting or handling fibers and dispose of fiber scraps properly to avoid injury. Follow recommended manufacturer procedures for battery charging and storage.

Handling fiber scraps and chemical safety

You’ll want to collect fiber shards in a designated container to prevent puncture injuries. Use alcohol and other solvents in well-ventilated areas, and store them in properly labeled containers.

Comparison to Other Units

You’ll find that the 6-motor configuration and core alignment place this unit closer to mid- to upper-range fusion splicers in terms of features. Many basic splicers use fewer motors or only cladding alignment, so this VEVOR unit offers advantages in speed and alignment precision.

When this is a better choice

If you need fast splicing with reliable alignment for both multimode and single-mode fibers, this machine offers a strong balance of features for its category. The large battery and bundled kit make it particularly suited for field technicians.

Limitations to consider

Some pro-grade splicers offer additional advanced features like built-in OTDRs, more automated reporting, or specialized rugged certifications. If you require those, you’ll want to compare specific higher-end models.

Pros and Cons

Below you’ll find a concise list to help you weigh the decision.

Pros

- Fast splicing (6s) and quick heating (13s).

- Core alignment and 6 motors for improved accuracy.

- Very low claimed fusion loss for multimode (0.01 dB).

- Large, clear 5-inch touch screen with multiple magnification modes.

- Long battery life (7800mAh) for extended field use.

- Comprehensive accessory kit included.

- Durable ABS/PC construction; designed for field conditions.

- 3-in-1 holder supports many fiber types.

Cons

- Manufacturer’s loss figure is for multimode; single-mode loss depends on many variables.

- Some advanced features found in very high-end splicers (e.g., integrated OTDR) may be absent.

- You’ll still need quality cleavers and good field technique to achieve the best results.

- Exact weight and certain environmental ratings are not specified in the product summary, so confirm if you need specific certifications.

Real-world Use Cases

You’ll find this machine useful across a variety of scenarios: last-mile fiber installations, enterprise backbone repairs, CATV maintenance, and field splicing for rural deployments. The kit and battery support long days in the field while the quick cycle times reduce downtime on multi-splice jobs.

Workflows where this shines

- Multi-drop fiber runs where you need to make many splices quickly.

- Remote repairs where long battery life and rugged construction are essential.

- Mixed-mode environments where you switch often between SM and MM fibers.

Tips for Getting the Best Results

You’ll get the best performance out of the splicer by pairing it with a quality cleaver and maintaining consistent cleaning discipline. Also, practice with the device in a controlled environment before taking it to a critical field job.

- Keep spare consumables like electrodes and heat shrink tubes in your kit.

- Periodically check firmware updates from the manufacturer if available.

- Train your team on consistent cleave lengths and cleaning routines.

Warranty and Support Considerations

You should check the vendor’s warranty terms and after-sales support policies before purchase. Good technical support and available spare parts can be crucial if you depend on the machine for daily operations.

Final Recommendation

If you need a feature-rich, fast, and portable fusion splicer for field and enterprise use, the VEVOR Fiber Optic Welding Machine with 6 Motors, Core Alignment, Splicing Machine, 6s Splicing & 13s Heating, Fusion Splicer with 5 Inch Touch Screen, 3 in 1 Fiber Holder, 7800mAh Battery for SM MM DS is a strong candidate. It gives you many professional features—core alignment, multiple magnification modes, long battery life, and a complete accessory kit—that help you get reliable results quickly.

If any specific advanced needs are critical (integrated advanced diagnostics or certified ruggedization levels), verify those with the seller or consider higher-tier models. Otherwise, for most field and installation purposes, you’ll likely find the value, speed, and portability well-suited to your work.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.