Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you ready to upgrade your welding setup with a single machine that handles aluminum, steel, and stick welding without forcing you to buy separate units?

Quick verdict

You’re getting a very versatile machine in the VEVOR TIG Welder, 225A 6-In-1 Aluminum Welding Machine (Large LED Display)- AC TIG/DC TIG/AC Pulse TIG/DC Pulse TIG/Spot TIG/MMA(Stick), 110&220V Dual Voltage Electric Welder with IGBT Inverter. It’s designed to be a one-stop tool for a wide range of metalworking tasks, delivering solid performance for DIYers, hobbyists, and light professional use.

Product overview

This VEVOR TIG welder packs six modes—AC TIG, DC TIG, AC Pulse TIG, DC Pulse TIG, Spot TIG, and MMA/Stick—into one inverter-based package with a large LED display. You’ll appreciate the compatibility with spool guns for aluminum, the high-frequency non-contact start, and protections like VRD and overheat/overcurrent safeguards that protect both you and the machine.

Key features at a glance

You’ll find several features that make this machine useful on a variety of projects, from garage repairs to farm equipment maintenance. Below I summarize the features you’ll likely use most and why they matter.

6-in-1 welding modes

This unit supports AC TIG for aluminum, DC TIG for steels, pulse TIG modes for better heat control and cosmetics, spot TIG for localized bonding, and MMA/Stick for traditional electrode work. You’ll be able to switch between modes depending on material and joint type, saving time and equipment cost.

Aluminum welding and spool gun compatibility

If you plan to weld aluminum, this welder accommodates spool guns designed for aluminum feed to prevent birdnesting and feed interruptions. You’ll get smooth wire feeding thanks to an optimized wire path, which is crucial for clean aluminum welds.

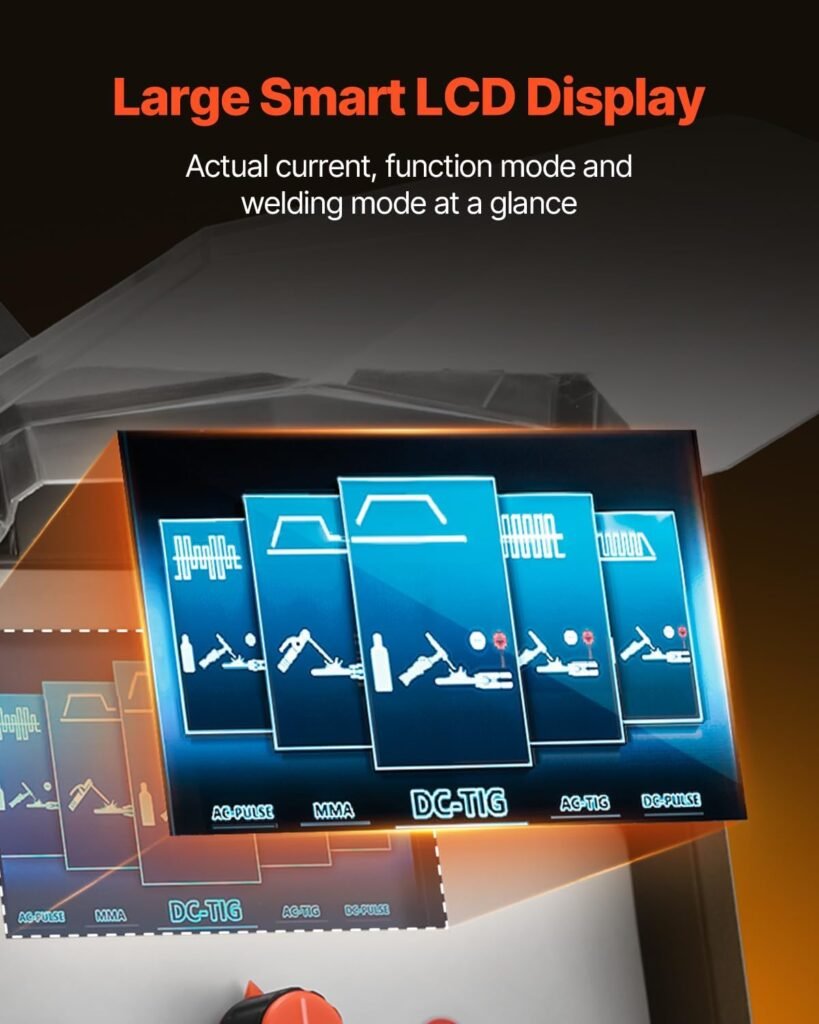

Smart LED display

The large, digital LED display gives you clear, real-time readouts of current settings, mode, and parameters so you can make precise adjustments. You’ll find it easier to set up pulse parameters, balance, and frequency without guessing.

High-frequency non-contact start

You’ll benefit from the high-frequency arc start that initiates the arc without touching the workpiece, reducing contamination and tungsten sticking. This method helps maintain a stable arc and cleaner welds from the first strike.

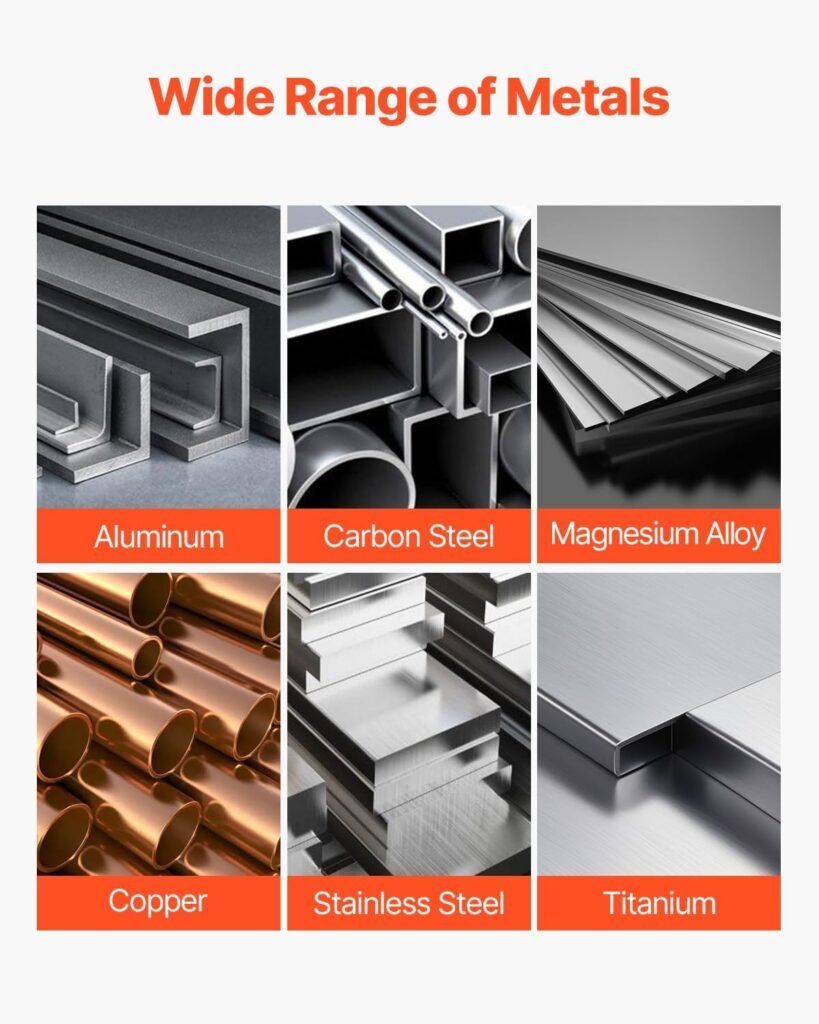

Materials and electrode compatibility

You can weld carbon steel, stainless steel, copper, and titanium with this machine, and it supports common electrodes like 6010, 6011, 6013, and 7018 for stick welding. You’ll also be able to handle up to roughly 1/4″ aluminum and 3/8″ low carbon steel under typical conditions.

Protection features and safety

The unit includes VRD (voltage reduction device), overcurrent, overvoltage, overload, and overheat protection to protect both the welder and you. These built-in protections help avoid damage during misuse or electrical spikes and increase reliability on job sites.

Technical specifications table

You’ll find this table useful for a quick comparison of the most relevant specs and what they mean for your projects.

| Specification | Detail | Why it matters to you |

|---|---|---|

| Model | VEVOR TIG Welder, 225A 6-In-1 | Identifies the exact machine and capabilities |

| Welding modes | AC TIG / DC TIG / AC Pulse / DC Pulse / Spot TIG / MMA (Stick) | Flexibility to handle many materials and joints |

| Max current | 225 A | Enough power for medium-thickness metals |

| Voltage input | 110 & 220 V (dual voltage) | Use it at home or on jobsites with different supplies |

| Start | High-frequency non-contact | Cleaner starts and less tungsten contamination |

| Display | Large LED digital display | Easier to dial in precise settings |

| Materials | Carbon steel, stainless, copper, titanium, aluminum (with spool gun) | Broad material compatibility |

| Electrodes | 6010, 6011, 6013, 7018 | Standard stick electrodes supported |

| Protection | VRD, overcurrent, overvoltage, overload, overheat | Safer operation and machine protection |

| Aluminum weld capability | Up to 1/4″ (with spool gun) | Good for many hobby and light fabrication tasks |

| Low carbon steel capability | Up to 3/8″ | Useful for typical shop repairs and fabrication |

| Inverter type | IGBT | Efficient, compact power delivery and better arc control |

Performance and welding quality

You want a machine that gives consistent arc behavior, dependable starts, and responsive control over heat input, and this VEVOR tries to deliver that balance. Below I cover how it performs across its different modes and materials.

TIG performance on aluminum

When you attach a spool gun and set the machine to AC TIG, the welder gives you the necessary AC balance and frequency options to manage heat and oxide removal. You’ll find it produces clean beads on thin to moderate thickness aluminum if you maintain a consistent travel speed and pulsing when needed.

TIG performance on steel, stainless, and titanium

On DC TIG, the arc is stable and controllable, making it appropriate for fine work on stainless and titanium as well as routine steel fabrication. You’ll get good penetration with the proper amperage, and the pulse modes will help you manage heat input for thin materials.

MMA/Stick performance

In stick mode, the VEVOR unit handles common electrodes well and produces reliable arcs even in windy or outdoor environments where GTAW isn’t practical. You’ll find stick welding useful for structural repairs and jobs where joint fit-up is poor.

Pulse modes and heat control

Pulse TIG modes (AC and DC) allow you to modulate heat input and control bead profile without compromising penetration too much. You’ll be able to weld thinner metals with less distortion and achieve better bead appearance on visible projects.

Usability and controls

This machine is designed with usability in mind, whether you’re a beginner or a seasoned operator looking for a compact multi-process unit. You’ll appreciate intuitive controls and a readable LED that reduce the trial-and-error learning curve.

Control layout and LED interface

The LED display clearly shows amps, mode, and pulse settings so you can fine-tune parameters faster than with analog dials. You’ll like how the digital readout keeps things consistent from one joint to the next.

Setup and installation

You’ll find the initial setup straightforward: attach the correct torch or electrode holder, choose the appropriate mode, set gas and current, and you’re ready. If you’re switching between spool gun and TIG torch, allow a few extra minutes for internal feed adjustments.

Wire feed and spool gun setup

The optimized wire path minimizes feeding problems and the spool gun compatibility is key for smooth aluminum welding. You’ll need to ensure proper pinching pressure and set the feed speed correctly to avoid birdnesting or slipping.

Dual voltage operation (110/220V)

You’ll be able to run the machine on a standard household 110 V outlet for lighter tasks, and switch to 220 V for maximum power when you need it. This versatility makes it practical for both shop and remote work.

Build quality and portability

The VEVOR welder has a compact, inverter-based design that keeps it relatively lightweight compared to older transformer welders. You’ll notice a sturdy case with handles that make it easier to move between garage, shop, or field locations.

Internal components and IGBT inverter

The IGBT inverter provides efficient power conversion and a more stable arc than basic transformer designs. You’ll get better energy efficiency and less heat build-up, which is helpful for longer sessions.

Cooling and durability

Built-in fans and thermal sensors help keep temperatures in check and prevent premature wear. You’ll still want to avoid running at maximum duty cycle for long stretches without breaks to extend the longevity of the unit.

Accessories included and additional purchases

You’ll usually get a standard set of accessories and will likely need a few extras depending on your intended work. Below are common items that come with similar welders and items you should plan to purchase.

- Typical included items: TIG torch, ground clamp and lead, electrode holder, basic consumables, and a user manual. You’ll be ready to start simple TIG and stick tasks right away.

- Recommended additional purchases: spool gun for aluminum, argon gas cylinder and regulator, higher quality TIG torch consumables (collets, cups, tungsten), protective gear (helmet, gloves, jacket), and possibly a foot pedal or remote for advanced control. You’ll notice improved results and convenience once you add these accessories.

Safety tips and best practices

Safety matters every time you weld, and the VEVOR includes several protective features but you still need to follow practices that protect your health and work. Below are important reminders for safe operation.

- Personal protective equipment: Always use a proper welding helmet with correct shade, gloves, long-sleeve flame-resistant clothing, and closed-toe shoes. You’ll reduce burn and UV exposure risks by being fully protected.

- Ventilation: Provide adequate ventilation or local fume extraction when welding stainless, titanium, or coated metals to avoid breathing hazardous fumes. You’ll protect your lungs and comply with safe workspace practices.

- Grounding and hookups: Ensure proper grounding and secure electrical connections, particularly when switching between 110V and 220V configurations. You’ll avoid electrical hazards and improve arc stability.

- Hot metal handling: Allow proper cooling time or use tools when moving welded pieces. You’ll prevent burns and accidental damage to welded assemblies.

- Routine checks: Inspect cables, connectors, and torches for wear or damage before each session. You’ll catch small problems before they become safety issues.

Welding settings recommendations

You’ll find the right amperage and settings depend on material thickness, joint type, and electrode or filler. Here are practical starting points that you can tweak to match your technique.

- 1/16″ to 1/8″ aluminum: Start around 40–100 A with AC TIG and adjust balance/frequency for cleanliness. You’ll use lower amps with pulse to reduce burn-through.

- 1/8″ to 1/4″ aluminum: 100–180 A depending on joint and filler thickness. You’ll need higher amperage for thicker sections and potentially a spool gun for consistent feed.

- 1/8″ low carbon steel (TIG/DC): 60–120 A depending on joint. You’ll adjust down for thin sections to avoid warping.

- 3/8″ low carbon steel (MMA/Stick): Use stick mode with appropriate electrode (e.g., 7018) at recommended amperage printed on electrode packaging. You’ll get deeper penetration with proper amperage.

Maintenance and troubleshooting

Caring for your machine will help it last longer and perform more reliably. You’ll find routine maintenance simple and troubleshooting manageable with a few basic checks.

Routine maintenance

Clean fans and air vents regularly, check cable insulation for cracks, and inspect torch consumables for wear. You’ll extend component life and reduce the chance of overheating or feed problems.

Common troubleshooting steps

If the machine won’t start, check input voltage and fuses; if arc starts but is unstable, inspect ground connections and torch cleanliness. You’ll often resolve issues by checking simple items like gas flow, tungsten contamination, and cable integrity.

When to call support

If internal components show electrical failures (odd smells, burning, or repeated protection trips) you should stop and contact the manufacturer or a certified technician. You’ll avoid dangerous situations by not attempting complex internal repairs beyond simple maintenance.

Comparison with similar welders

You’ll likely compare this VEVOR unit to other multi-process TIG inverters in the same price bracket. Below are common strengths and trade-offs versus alternatives.

Where this machine shines

Its multi-mode capability and spool gun compatibility make it a very flexible choice for a DIYer or small shop that wants TIG and stick in one box. You’ll value the LED interface, HF start, and included protections for day-to-day use.

Where it falls short

If you’re a production welder requiring very high duty cycles or specialized plasma cuts, you might find the duty cycle and continuous heavy use limits restrictive. You’ll also need to budget for quality consumables and spool gun if you plan heavy aluminum work.

Pros and cons table

You’ll find this side-by-side view helpful to weigh advantages against limitations quickly.

| Pros | Cons |

|---|---|

| Six modes in one machine (AC/DC TIG, pulse, spot, MMA) | Duty cycle limited compared to larger industrial machines |

| Spool gun compatibility for aluminum | Spool gun may be sold separately depending on package |

| Large LED display and digital controls | Learning curve for beginners new to pulse and balance settings |

| Dual voltage operation (110/220V) | At max output, cooling breaks are necessary for long runs |

| Multiple safety protections (VRD, overheat, overcurrent) | Build quality is good but not as rugged as top-end brands |

Who should buy this

You should consider this VEVOR TIG welder if you do a mix of TIG and stick work around the home, garage, or small shop and want one machine that covers aluminum and steel. You’ll especially benefit if you need portability and dual-voltage flexibility without buying separate specialized machines.

Who might want a different machine

If you regularly weld heavy, thick plate in high-volume production or need extremely long duty cycles, a larger dedicated industrial TIG or MIG welder may suit you better. You’ll want to consider higher-duty industrial units for continuous shop production.

Practical project ideas you can tackle

This machine lets you work on a wide range of projects that would otherwise need multiple welders. You’ll be able to repair farm implements, fabricate bike frames, restore small aluminum panels, build light structural frames, and handle general shop repairs.

- Aluminum patch panels and thin-sheet repairs: Use AC TIG with spool gun for controlled heat and clean beads. You’ll get much better cosmetic results than stick welding.

- Bike or motorcycle components (steel/titanium): Use DC TIG for precise, clean welds. You’ll appreciate the control for thin-wall tubing.

- Gate and railing repair: Use MMA/Stick for quick field repairs where access to shielding gas or clean surfaces is limited. You’ll find stick mode tolerant of dirty conditions.

- Automotive panels and brackets: Use pulse modes to reduce warping on thin metals. You’ll preserve fit and finish while achieving structural integrity.

Final verdict

You’ll find the VEVOR TIG Welder, 225A 6-In-1 Aluminum Welding Machine (Large LED Display)- AC TIG/DC TIG/AC Pulse TIG/DC Pulse TIG/Spot TIG/MMA(Stick), 110&220V Dual Voltage Electric Welder with IGBT Inverter to be a strong value if you need multi-process flexibility in a compact package. It’s not a heavy industrial powerhouse, but for most hobbyists, fabricators, and light-shop professionals it offers the features, safety, and performance that make it a practical, cost-effective choice.

Frequently asked questions (FAQ)

You’ll probably have a few common questions before buying; here are clear answers to typical concerns.

Q: Can this unit weld thick aluminum? A: You can weld aluminum up to about 1/4″ with a spool gun and correct settings; for thicker plate you’ll need higher amperage equipment. You’ll get the best results when you match filler, travel speed, and cleaning to the material thickness.

Q: Do I need a spool gun for aluminum? A: For most aluminum welding you’ll want a spool gun to prevent wire-feed problems and birdnesting. You’ll be able to weld thinner aluminum without one only with great care using specialized aluminum feeders, but a spool gun is strongly recommended.

Q: Is this suitable for a beginner? A: Yes, it’s usable by beginners, especially given the LED readouts and digital controls, but you’ll need some practice to master AC balance, pulse settings, and tungsten preparation. You’ll learn faster if you start with thin scrap pieces and progressively adjust settings.

Q: How portable is the machine? A: It’s reasonably portable compared to older transformer welders thanks to the IGBT inverter design and compact case. You’ll still need to plan for gas cylinders, spool guns, and cables when moving the setup.

Q: What additional gear should I buy immediately? A: You’ll want a quality welding helmet, argon gas and regulator, spool gun for aluminum (if needed), and quality TIG consumables to get the best results. You’ll see performance gains with better consumables and proper gas flow.

Q: What’s the duty cycle like? A: Duty cycle varies with current and voltage; at maximum output the duty cycle will be limited compared to larger industrial welders. You’ll need to monitor run time and allow cooling periods during long jobs to protect the inverter.

If you want, I can provide recommended amperage charts for specific joint types, a shopping checklist for accessories (spool gun models, regulators, consumables), or a step-by-step beginner setup guide for a first aluminum TIG weld. Which would you like next?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.