Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

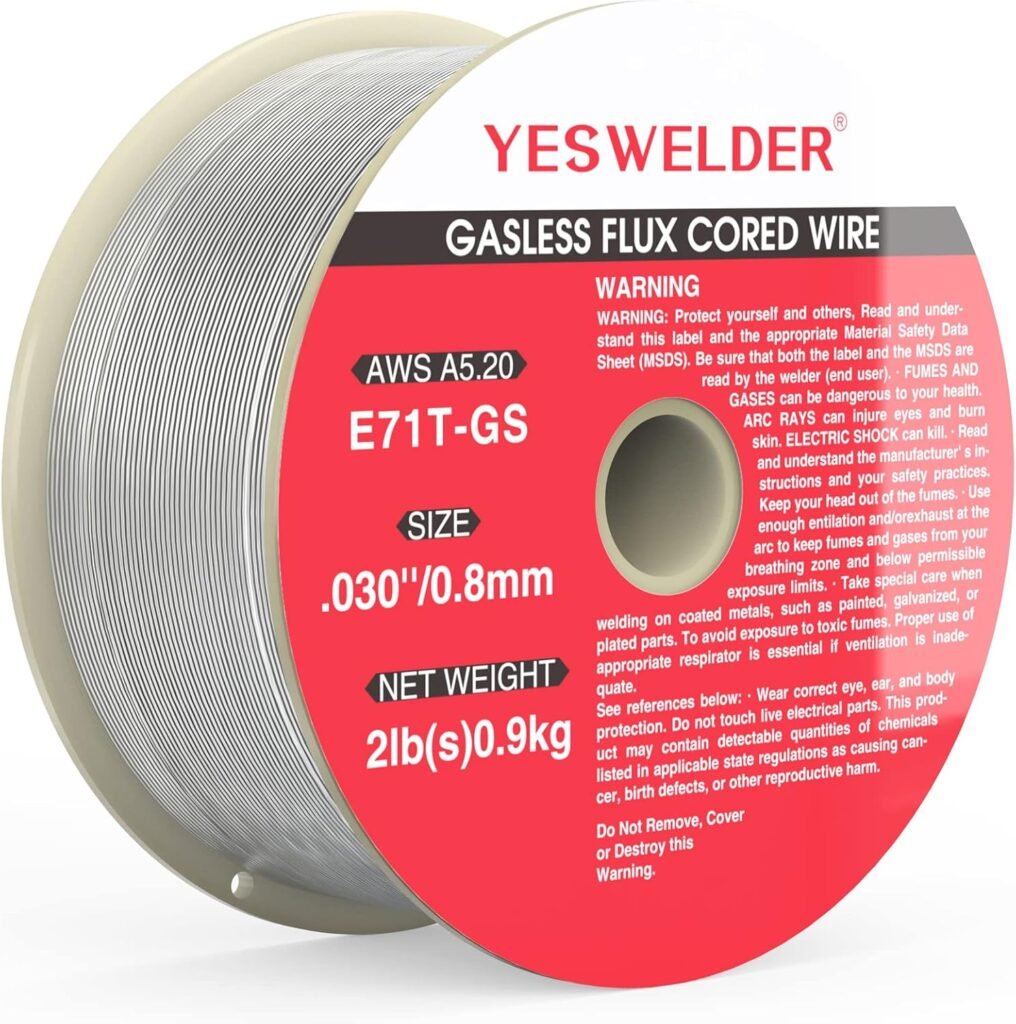

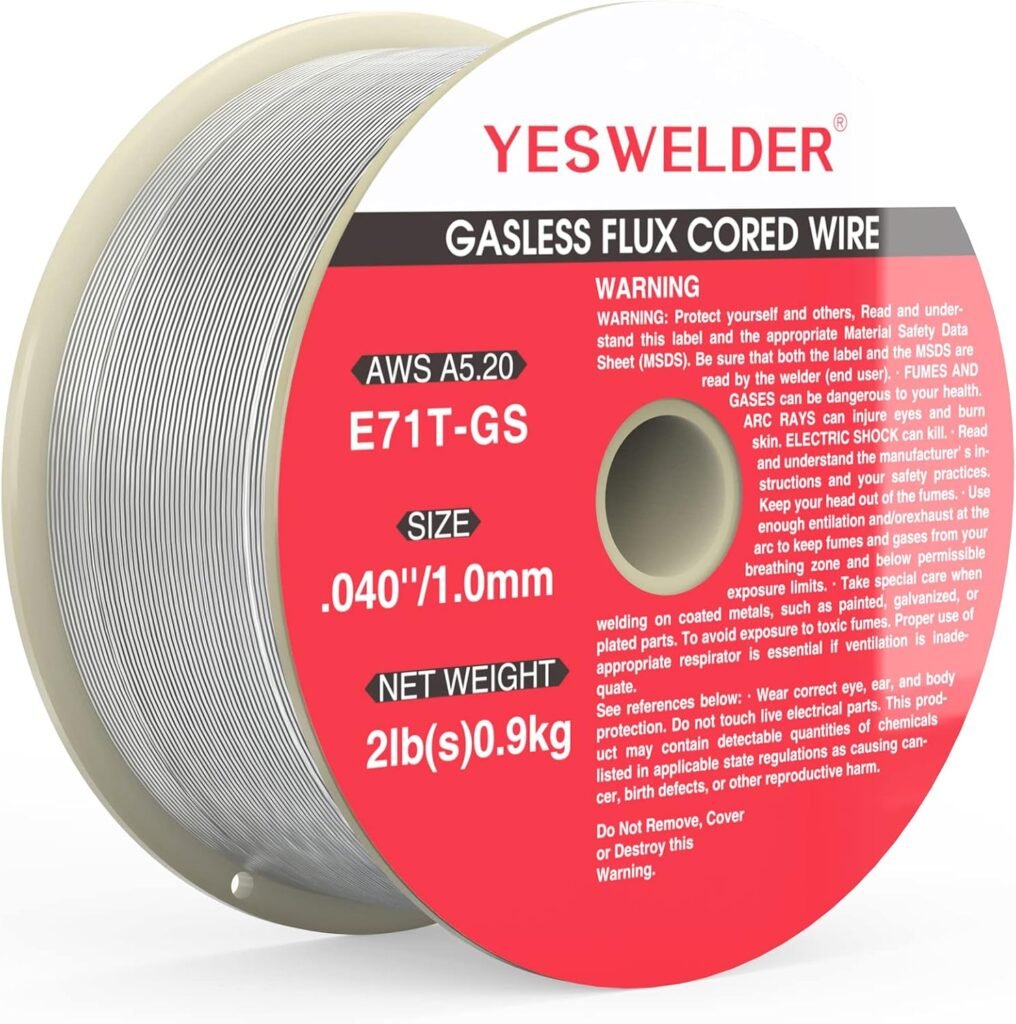

Introducing the YESWELDER Flux Core Gasless MIG Welding Wire, an essential tool for your welding needs. This high-quality mild steel wire, with a 0.8mm diameter and a 0.9kg spool, offers smooth arc action and exceptional feedability, ensuring an effortless welding experience. It shines in all positions and performs well in single and multi-pass welding, making it versatile for various projects. With low spatter, full slag coverage, and easy slag removal, it guarantees a clean, porosity-free finish and a good bead appearance under challenging outdoor conditions. The need for shielding gas is eliminated, ensuring convenience and reliability. Have you ever been frustrated with welding because of the need for a shielding gas or dealing with excess spatter and messy slag removal? If so, you’re not alone. Many hobbyists and professionals alike seek a welding wire that simplifies their work without compromising on quality. That’s where the YESWELDER Flux Core Gasless MIG Welding Wire, Mild Steel E71T-GS 0.8mm 0.9kg Spool, comes in to save the day!

Why Choose YESWELDER Flux Core Gasless MIG Welding Wire?

When it comes to welding, the quality of your wire plays a crucial role in determining the final outcome of your project. The YESWELDER Flux Core Gasless MIG Welding Wire offers various advantages that make it a standout option for welders at all levels.

Gasless Convenience

One of the most significant benefits of this wire is that it is gasless. This means you don’t have to worry about carrying around a cumbersome gas cylinder or dealing with the costs associated with gas refills. Just load the wire into your MIG welder, and you’re ready to go!

Features at a Glance

To make things simpler, here’s a quick breakdown of what you can expect from the YESWELDER Flux Core Gasless MIG Welding Wire:

| Feature | Description |

|---|---|

| Wire Type | Flux Core, Gasless |

| Material | Mild Steel |

| Diameter | 0.8mm |

| Weight | 0.9kg Spool |

| Arc Action | Smooth |

| Feedability | High |

| Shielding Gas | Not Required |

| Position | All Positions |

| Pass Welding | Single and Multi-pass |

| Spatter Level | Low |

| Slag Removal | Easy |

| Porosity | Free |

| Bead Appearance | Good |

| Outdoor Usability | Excellent in Windy Conditions |

Smooth Arc Action and High Feedability

This wire provides a smooth arc action, meaning that your welds will be more consistent and cleaner, with fewer complications. High feedability ensures that you can maintain a steady pace while welding, without frequent stops and starts.

Ease of Welding and No Shielding Gas Required

The YESWELDER wire is user-friendly, making it a good option even for beginners. Its gasless nature removes the need for a shielding gas, reducing extra costs and complexities.

Performance in Different Conditions

Now, let’s dive deeper into how this welding wire performs under various conditions. Whether you’re working indoors or dealing with outdoor elements, this wire aims to stand the test.

All Position Welding

One of the most useful features of the YESWELDER Flux Core Gasless MIG Welding Wire is its ability to weld in all positions — be it flat, horizontal, vertical, or overhead. This versatility makes it perfect for a wide range of applications.

Single and Multi-Pass Welding

Whether you’re laying down a single pass weld or building up multi-pass layers, this wire has got you covered. It adapts well and maintains its quality throughout the process.

Low Spatter and Full Slag Coverage

Welding can often be a messy activity, but not with this product. The low spatter levels mean there’s less cleanup required after welding, and full slag coverage ensures the welds are solid and clean. Plus, the slag is easy to remove, making post-weld processing much more straightforward.

Porosity-Free and Good Bead Appearance

Porosity is a common problem that can compromise the integrity of your welds. This wire eliminates that issue, providing porosity-free welds. You’ll also appreciate the good bead appearance, ensuring that your welds look professional and neat.

Excellent for Outdoor Windy Conditions

If you’re someone who often finds themselves welding outdoors, this wire is particularly advantageous. Its gasless design and robust performance hold up well even in windy conditions, ensuring you get the job done right, no matter the environment.

Detailed User Experience

You might be wondering what it’s like to actually use this product. Let’s delve into the real-world experience of using YESWELDER Flux Core Gasless MIG Welding Wire.

First Impressions

The spool is well-packaged, ensuring that the wire is in perfect condition when it arrives. Unpacking it, you’ll quickly notice its high-quality build, giving you confidence in its performance right from the start.

Setting Up

Setting up the wire in your MIG welder is a breeze. Thanks to its high feedability, it fits seamlessly into most machines without any hitches. Once installed, you can immediately tell that it feeds smoothly, allowing for a consistent welding experience.

Actual Welding

When you start welding, the smooth arc action becomes immediately noticeable. The wire lights up effortlessly, providing a steady arc that is easy to control. This is particularly helpful for beginners who are still getting the hang of welding.

After Welding

Post-weld cleanup is minimal. You’ll find that the slag is easily removable, and there’s very little spatter to deal with. The end result? Clean, porosity-free, and visually appealing welds that you can be proud of.

Overall Satisfaction

Overall, users report high levels of satisfaction with this product. It offers a simpler, more cost-effective way to achieve professional-grade welds without the need for shielding gas or extensive post-weld cleanup.

Comparison with Other Welding Wires

You might still be wondering how the YESWELDER Flux Core Gasless MIG Welding Wire stacks up against other options on the market. Let’s compare it to a couple of popular alternatives.

Comparison Table

Here’s a comparison table to give you a clearer picture:

| Feature | YESWELDER Flux Core (E71T-GS) | Brand X Flux Core | Brand Y Solid MIG (Requires Gas) |

|---|---|---|---|

| Wire Type | Flux Core, Gasless | Flux Core, Gasless | Solid, Requires Gas |

| Diameter | 0.8mm | 0.9mm | 0.8mm |

| Weight | 0.9kg Spool | 0.9kg Spool | 1kg Spool |

| Smooth Arc Action | Yes | Moderate | Yes |

| High Feedability | Yes | No | Yes |

| Shielding Gas Required | No | No | Yes |

| All Position Welding | Yes | Yes | No |

| Single and Multi-Pass | Yes | Limited | Yes |

| Low Spatter | Yes | High | Moderate |

| Easy Slag Removal | Yes | Moderate | N/A |

| Porosity | Free | Minimal | Free |

| Good Bead Appearance | Yes | Average | Yes |

| Outdoor Windy Condition Use | Excellent | Poor | Not Recommended |

Tips for Using YESWELDER Flux Core Gasless MIG Welding Wire

To help you get the best performance, here are some tips for using the YESWELDER Flux Core Gasless MIG Welding Wire:

Adjust Your Settings

Ensure that your MIG welder settings are appropriately adjusted for flux core wire welding. This usually means adjusting the voltage and wire feed speed to suit the 0.8mm diameter of the wire.

Clean Your Work Surface

Although flux core welding is more forgiving on dirty or rusty surfaces, it’s still a good idea to clean your work surface as much as possible. This ensures better arc stability and a higher quality weld.

Use the Right Technique

Maintain a steady hand and use the right technique for flux core welding. Holding the welding gun at a slight angle can help in achieving better results.

Safety First

Always prioritize safety by wearing appropriate personal protective equipment (PPE), including gloves, welding helmets, and protective clothing. The flux core welding process can produce significant amounts of smoke and spatter, so make sure you are adequately protected.

Common Issues and Troubleshooting

While the YESWELDER wire is user-friendly, you might run into some common issues. Here’s a quick troubleshooting guide to help you out.

Inconsistent Wire Feed

If you experience inconsistent wire feed, check the wire tension and make sure it’s appropriately adjusted. Also, make sure the MIG gun liner isn’t dirty or kinked.

Excessive Spatter

If you’re noticing more spatter than expected, try adjusting your voltage and wire feed speed. Sometimes a minor tweak can make all the difference.

Poor Penetration

If your welds are not penetrating well, increase the voltage slightly. Ensure that you maintain a consistent travel speed while welding to avoid this issue.

Final Thoughts

The YESWELDER Flux Core Gasless MIG Welding Wire, Mild Steel E71T-GS 0.8mm 0.9kg Spool, has set a high bar in the world of welding. Its gasless nature, ease of use, and high-quality welds make it an excellent choice for both DIY enthusiasts and seasoned welders. By eliminating the need for shielding gas, it offers a level of convenience and cost-effectiveness that is hard to beat. Whether you’re welding indoors or braving the elements outdoors, this wire promises to deliver reliable and professional results every time.

So, what are you waiting for? Give the YESWELDER Flux Core Gasless MIG Welding Wire a try, and experience the difference for yourself. Happy welding!

Disclosure: As an Amazon Associate, I earn from qualifying purchases.